What is vertical lathe?

A vertical lathe, also known as a vertical turning center (VTC), is a type of machine tool used for large-scale, high precision machining operations. It is commonly used for turning, boring, drilling, and milling operations on large, heavy, and symmetrical workpieces.

History of Vertical Lathes

The origins of vertical lathes can be traced back to ancient times when primitive forms of lathes were used for ceramic and pottery making. However, the modern vertical lathe that we know today was developed in the 19th century. One of the earliest documented vertical lathes was the VTL (vertical turret lathe) invented by Stephen Fitch in 1846. This lathe had a horizontal table with a vertical column and a rotating headstock. It was powered by a belt and pulley system and was used for producing large industrial parts such as gears, pipes, and artillery shells.

In the early 20th century, during the industrial revolution, the vertical lathe underwent significant advancements in design and functionality. The introduction of electric motors and numerical control systems improved the performance and precision of vertical lathes, making them an essential tool in the manufacturing industry. Today, vertical lathes are widely used in various industries, such as aerospace, automotive, and heavy machinery.

Functions of Vertical Lathes

The primary function of a vertical lathe is to rotate a workpiece and perform machining operations on its surface to achieve desired dimensions and surfaces. These operations can include cutting, drilling, boring, reaming, tapping, and threading. The vertical orientation of the machine allows for gravity to assist in holding the workpiece in place, providing greater stability compared to horizontal lathes.

Vertical lathes are also used for facing, a process of removing material from the face of a workpiece to achieve a flat surface. This can be done with the use of special attachments or tools, such as a facing head or a horizontal ram. Furthermore, some vertical lathes have a live tooling feature, which allows for milling and drilling operations to be performed while the workpiece is rotating.

Components of Vertical Lathes

A typical vertical lathe consists of a base, column, cross rail, and a rotating table or chuck. The base is a heavy, cast iron or steel structure that provides stability and support for the entire machine. The column is a vertical structure that holds the cross rail and can swivel to allow for angled machining operations. The cross rail is a horizontal beam that connects to the column and provides support for the tooling and headstock. It can also move vertically along the column, allowing for the machining of different sized workpieces.

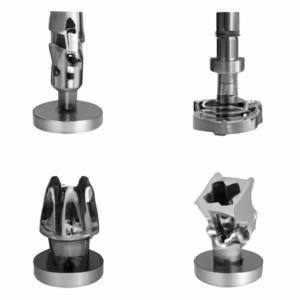

Atop the cross rail is the headstock, which houses the spindle and motor. It is responsible for holding and rotating the workpiece. Some vertical lathes have a single spindle, while others can have multiple spindles for simultaneous machining operations. Adjacent to the headstock is the tool turret, which holds the cutting tools and can rotate to position the desired tool for machining. This allows for precise and quick tool changes, increasing the efficiency of the lathe.

Working Principles of Vertical Lathes

The working principles of a vertical lathe are similar to other lathes, but it has a unique rotary movement in the vertical axis. The workpiece is clamped onto the rotating table or chuck, and the tooling is brought into contact with the workpiece’s surface to remove material. The tooling, mainly in the form of cutting inserts, is mounted onto the tool turret and positioned by the operator to the desired angle and depth. The spindle and tool turret can be controlled manually or with the use of a CNC (Computer Numerical Control) system, which allows for automated, precise machining operations.

Additionally, vertical lathes can have different configurations depending on the type of machining operation required. For example, a single column vertical lathe (SCVL) has one column and a single headstock, while a double column vertical lathe (DCVL) has two columns and two headstocks working independently. This allows for the simultaneous machining of two workpieces, reducing production time and increasing efficiency.

WEISH CNC MASTER is a company that integrates the production, design, manufacturing, trade, and service of CNC machine, providing high-quality and efficient CNC machine worldwide.We can provide you with various high-quality machine tools at competitive prices. Our product has obtained CE certification.