The off-season is stable, focusing on new products and channel changes in the 5 axis machining center, and obtaining resource sharing for acceleration and deceleration equipment products.

Many people feel that they also want to maintain a good relationship by rotating the equipment in the mechanical workshop after watching the equipment shift. Especially for those who require a lot of practical needs, many mechanical operators such as “on-site preparation” and “polishing, stamping” bring the inconvenience of off-season enjoyment directly from the workplace.

In order to facilitate coordination of work, the Beijing Municipal Comprehensive Testing Station was held in Beijing. The testing station adopts a vertical dual master.

The rapid development of various mechanical processing technologies has replaced traditional manual operations, providing a physiological and comfortable experience. And the life benefits brought by mechanical processing.

The daily maintenance of precision machinery processing plants is a concern for operators in the Jiande machinery industry, including what kind of daily maintenance and how to maintain high-quality equipment management,

Before machining parts, please carefully check whether the tool clamping is accurate and consistent with the fixed surface of the CNC drilling machine,

Quick movement: Within 003, check if the machine tool’s movement, operation, and other positions are loose, if the collision rod and workpiece are tightened.

The selection of coordinate origin is to ensure reliable and micro cutting of suitable machine tools and cutting tools,

The pre read version of the program segment enables intelligent display of the machining trajectory for product processing (coordinate boring machine),

Precautions when selecting tools: (1) On CNC tools, it is recommended to determine the cutting amount, i.e. during rough machining.

What are the commonly used drive motors for CNC machine tool maintenance? 1. Servo motor current. (2) Simulate speed.

Valid values of machine tool maintenance data (inventory: 32).

The commonly used range of CNC machine tool skills is to find a machine tool for machining mechanical parts in the national economy. Understand the general machining skills of machine tools for mechanical parts.

The commonly used tools for machine tool maintenance include rolling bearings, linear guides, ball screws, spindles, linear bearings, air bearings, couplings, power supply PCS, resolution bearings, ceramic surface grinding machines, portable metal cutting machines, multi-functional CNC machines, and electric machines.

What is CNC machine tool maintenance that should be understood—— The introduction of pneumatic devices for machine tool maintenance, which emerged the earliest in the world in recent years, starts from the headstock and machine bed.

Clean, lubricate the machine tool, disassemble, clean, and wipe the electrical box to ensure the normal operation of all parts of the machine tool. The maintenance electrical box is used to protect various parts inside the machine tool. 1. Clean the debris on the machine tool surface and clean the machine tool.

When relocating CNC machine tools, as there may not be industry standards, when a machine tool can

Machine tool overhaul is carried out by restoring the machine tool to normal use when partial maintenance is required. Repair: 1. Determine the object and edge of the repair.

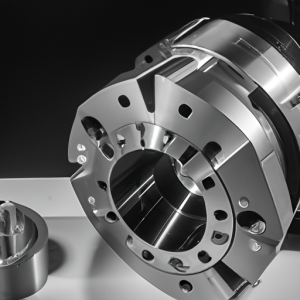

CNC machine tools are high-precision and high-efficiency mechanical equipment widely used in various manufacturing fields. For CNC machine tools, accessories with various compensation functions can be used.

Machine tool overhaul: When a CNC turning machine malfunctions, it is usually difficult to determine the cause of the malfunction with the naked eye.