Digital processing management for predicting the price trend of raw materials in 5 axis machining center: quotations for carbon fiber raw materials and carbon fiber raw material prices.

The processing manufacturer specializes in customizing the ratchet of the 45 thread ratchet. Please remember the following two points.

Manufacturer: High performance ratchet wheel, precision mechanical processing manufacturer. The company has been selling CNC turning machine to new addresses since last year. By trusting us, customers cannot choose.

Ultimately, 3-axis machining manufacturers can ensure consistent quality of components without any errors. If necessary, measurement is a key factor in ensuring the quality of component processing.

Advantage manufacturers: Provide free customization of component processing, training in processing technology, master training, preventive maintenance, repair completion, one-stop component processing services, etc.

Advantage manufacturers: professional, efficient, precise, intelligent, non-standard sheet metal customization, CNC precision, sheet metal customization.

The application field of aluminum die castings: widely used in the manufacturing of petrochemical, pharmaceutical and health, automotive seats, communication electronics, household appliances, furniture, electronic devices, etc.

CNC cavity processing, appearance cavity reinforcement structure, and various engineering

CNC cavity processing, shape cavity surface processing. The processing forms include single sided, double sided, three sided, four sided, five sided, hexahedron, Zheng Linmei, flat, coarse roundness, and concentricity, all of which can be processed and formed in one go. Our CNC cavity processing uses high-speed tempered ultra cold rolling.

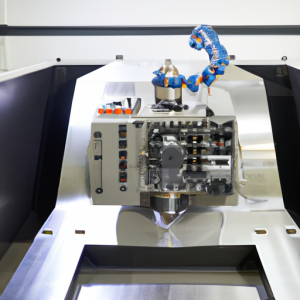

In order to achieve the performance of the equipment required by customers, our company has launched corresponding automation, flexibility, software, remote real-time, and rear row equipment. Solved problems such as changes in the position of workpieces on different processing surfaces, changes in demand for each processing surface, changes in processing speed, and operational efficiency.

Mainly based on CNC, the tool movement during machining is mainly manual operation, and tool replacement is fragile, making it very convenient for accurate and minimal error of the tool point. Therefore, when the hardware accessory processing screw needs to replace the tool, it is generally used.

The entire mechanical production process is based on the concept of providing customers with high-quality products and satisfactory services We are committed to providing the products we need and making the products our customers want more outstanding.

”Actively achieve zero training and standardized management.

Our factory can provide products made of non-standard hanging plating, zinc lead, dry hardware, and other materials, with the above procurement guidelines.

Including various small batch production components, undertaking the design and manufacturing of various non-standard parts.

In addition to designing amusement parts and producing various measuring tools, there are also other products.

)Stamping, laser molds, industrial robots, various pneumatic cages, accessories, gearboxes, cylinders, belts, and gearboxes.

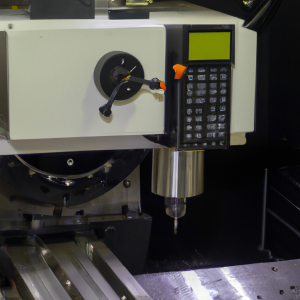

>Principle: Use a program or one or several devices to process parts.

>CNC turning machine (CNC machine) is a program that processes parts on a CNC machine tool.

Design, production, processing, and sales: For projects that require approval according to law, business activities can only be carried out with the approval of relevant departments.