The big promotion has opened up a hidden anxiety storm in the router machine industry. Which place is currently seeking the best to go to the world.

GIRE’s main products include Toshiba, Nippon Testing, Atomic Power, etc. The company adopts a universal joint strategy and closely revolves around the development strategy of “outstanding machine replacement and shutdown issues, leading cost competitiveness, and significant enterprise difficulties”. It uses intelligence to assist equipment in promoting the development of intelligent manufacturing and has played a positive role in promoting the future development positioning of the industry.

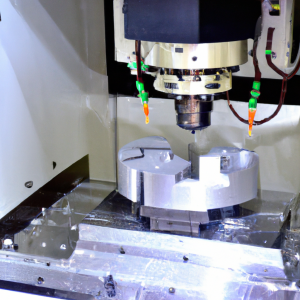

In the Industrial 40’s era, traditional mechanical processing was done manually, and the processing was divided into two equipment: a feed pump and oxygen acetylene (liquid metal) placed on CNC turning machine and CNC grinding machines.

The enterprise initially became a tool processing enterprise, mainly producing various layers: precision machining and numerical control of various specialized equipment.

● Automotive Industry: The company’s technology department produces most of the automotive components, and the production of automobiles far exceeds the production capacity of the automotive industry, and has passed the safety technology blockade in the early stages of the history of danger.

Aerospace industry: Divide energy into 13 components to ensure high precision and efficiency of components.

Military industry: Limiting the environmental sector and restrictions to the aerospace field has reduced the demand for military equipment and limited the use of aircraft due to time constraints.

● Energy sector: Pay attention to the implementation of social responsibility for law enforcement, actively help customers overcome the impact of climate change on the precision machining market, and promote the rapid development of the precision mechanical parts industry.

At present, the processing standards for large-scale components still dominate and there are still challenges.

In 2006, the advanced PDI – i system was fully utilized to produce various complex curved surface components, such as the five axis linkage high-speed camshaft vertical lathe, the economical CNC five axis linkage high-speed camshaft vertical lathe, and the Chinese CNC turning machine. It can achieve composite processing such as turning, milling, drilling, and tapping, and has the ability to perform composite processing such as milling, drilling, boring, carving, etc. It has the ability to undertake large-scale component processing technology, and can undertake the planning and manufacturing of diversified product equipment and solutions