How CNC Turning Lathe Automation Can Help Maximize Productivity in Your Manufacturing Facility

CNC turning lathe automation is a powerful tool for maximizing productivity in any manufacturing facility. By automating the process of turning, manufacturers can reduce labor costs, increase accuracy, and improve the overall quality of their products.

The automation of CNC turning lathes is achieved through the use of computer numerical control (CNC) systems. These systems are programmed to control the movement of the lathe, allowing for precise and repeatable operations. This eliminates the need for manual labor, which can be costly and time-consuming. Additionally, CNC systems can be programmed to perform multiple operations in a single cycle, further increasing efficiency.

CNC turning lathe automation also increases accuracy and consistency. By using a CNC system, manufacturers can ensure that each part is machined to the same exact specifications. This eliminates the need for manual inspection and rework, which can be costly and time-consuming. Additionally, CNC systems can be programmed to perform multiple operations in a single cycle, further increasing accuracy and consistency.

Finally, CNC turning lathe automation can help to improve the overall quality of the products being produced. By using a CNC system, manufacturers can ensure that each part is machined to the same exact specifications. This eliminates the need for manual inspection and rework, which can be costly and time-consuming. Additionally, CNC systems can be programmed to perform multiple operations in a single cycle, further increasing accuracy and consistency.

Overall, CNC turning lathe automation is a powerful tool for maximizing productivity in any manufacturing facility. By automating the process of turning, manufacturers can reduce labor costs, increase accuracy, and improve the overall quality of their products.

Exploring the Benefits of Automated CNC Turning Lathe Technology for Increased Productivity

The use of automated CNC turning lathe technology has revolutionized the manufacturing industry, providing increased productivity and efficiency. This technology has enabled manufacturers to produce high-quality parts with greater accuracy and precision, while reducing labor costs and increasing production speed.

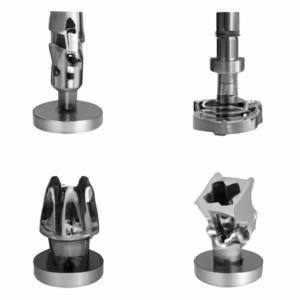

Automated CNC turning lathes are computer-controlled machines that use a variety of tools to shape and cut metal and other materials. The machine is programmed with a set of instructions that tell it how to move and rotate the material, as well as how to cut and shape it. This technology allows for greater accuracy and precision than manual turning lathes, as well as faster production speeds.

The use of automated CNC turning lathes has numerous benefits for manufacturers. First, it reduces labor costs by eliminating the need for manual labor. This technology also increases production speed, allowing manufacturers to produce more parts in less time. Additionally, automated CNC turning lathes provide greater accuracy and precision than manual turning lathes, resulting in higher quality parts.

The use of automated CNC turning lathes also provides increased safety for workers. This technology eliminates the need for manual labor, reducing the risk of injury or accidents. Additionally, automated CNC turning lathes are equipped with safety features such as emergency stop buttons and sensors that detect when a tool is not properly positioned.

Finally, automated CNC turning lathes are more cost-effective than manual turning lathes. This technology requires less maintenance and can be used for a longer period of time, resulting in lower operating costs. Additionally, automated CNC turning lathes are more efficient, allowing manufacturers to produce more parts in less time.

In conclusion, automated CNC turning lathe technology provides numerous benefits for manufacturers, including increased productivity, efficiency, accuracy, precision, safety, and cost-effectiveness. This technology has revolutionized the manufacturing industry, allowing manufacturers to produce high-quality parts with greater speed and accuracy.