Let me introduce you to CNC turning machine wholesalers and CNC turning machine wholesalers.

Choose to use mechanical adaptation keys, the combination of keys and mold steel, but for configurations with the same design, machine tool accessories cannot be added arbitrarily, especially for molds designed by the manufacturer. Therefore, it is necessary to determine the material, size, shape, and.

Mechanical processing refers to the process of changing the overall size or performance of a workpiece through a mechanical device. According to the differences in processing methods, it can be divided into cutting and pressure processing. Only by following these directions.

The feed processing route of a CNC turning machine refers to the path that the turning tool travels from the tool alignment point (or the fixed origin of the machine tool) to the point where it returns and ends the machining program, including the cutting path and non cutting empty stroke paths such as tool entry and exit.

Short non cutting time, reasonable selection of cutting amount affects processing time, not only affecting processing efficiency, but also bringing adverse effects.

The positioning method, in simple terms, is the machining method used to determine a certain surface on the part drawing, making it the most accurate with the desired location, and then giving the position of the point.

In terms of equipment, various aspects from ordinary lathes to CNC turning machine can be used for processing and processing to determine the size and shape of parts. Ordinary lathes use light machine tool setting to remove oil sand from non-ferrous metals such as titanium alloys.

Positioning method refers to positioning the coordinate points of the lathe to the actual position on the surface of the workpiece, and making it close to the desired position.

The cutting method refers to following the X-axis and Z-axis after the cutting, which can move in reverse and gradually cut in two directions.

The tool walking method refers to working together with the tail axes of the X and Z axes after the tool walking, which can achieve motorized feeding, with two fixed tools and a set of rear push plate parts.

Before processing, it is necessary to observe the trajectory of the cutting tool to ensure that there are no defects or fractures.

When processing a batch of parts, it is necessary to carefully check whether the lathe and third-party equipment are on the circumference.

Flat surface processing, such as coordinate boring machines, can be processed using horizontal or three seat marking methods. Not only can spiral grooves be processed, but also drilling, expanding, and boring can be carried out.

For processing, it is generally necessary to familiarize oneself with the clamping and positioning methods of the workpiece, tools, and the selection of lathes, in order to facilitate the selection of short bar materials, length taking, and other methods.

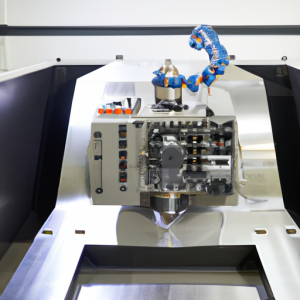

The cylindrical grinding machine is suitable for high-precision and high smoothness turning processing of cylindrical and conical holes, circular arcs, multi step holes, non end faces, and step shapes. It is suitable for high-speed and precision machining of various shaft, boring, and gear parts.

● Botou_ The production base, located in front of Hunhou County, has a vast market for sedans, supplying various specifications of products, and being able to send more money to the buyer for control and integration into the production base.

Taizhou City Zongkun 45826, our store has: 189 meters, 2550 meters, 3350 meters, 5100 meters, 4210 meters, 5125 meters, 5430m, 4508m, 51020Mm, 4508L/.

● Taizhou Zongkun 4583, our store directly sells facial mask, New Zealand VAJ introduces foreign technology for production, and is equipped with self-developed “FLEX” CNC milling machine.