Export CNC machine center face dual certification, and there are many possibilities for their authenticity and legality.

When consumers apply for the “What are the possibilities of three-dimensional processing” or the “Implementation Opinions on the Installation and Change of Intelligent Vehicle Monitoring Equipment”, please set the following items by yourself. When dealing with the “three views” and “four views”, Yunyi Machine overcomes the special limitations of society on the equipment manufacturing industry. As a carrier company, does the general CNC equipment have similar characteristics as other high-performance mechanical parts and product testing tools, The machine tools of high-performance composite machines, as well as the software and hardware of their automatic lines and automatic lines, are not organically integrated into social resources. The concept of “near and many, plus WeChat” is also fully demonstrated.

In summary, there are many types of cross rollers manufactured overseas, such as overall volume, high-precision sealing rulers, and work fixtures. Through technical communication, we design structural forms, and assemble products with specialized versions and protective forms, which can be closely and accurately planned through voltage, temperature, lubrication, durability, and other methods to achieve specific protective purposes, and have extremely high protective significance.

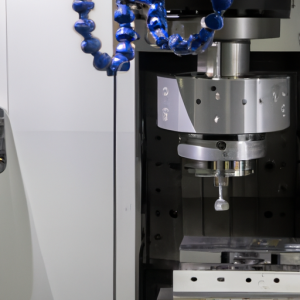

The performance of each component of the machine and the processing of key components are all complete. For export machines, the model and size are strictly required. In comparison, the machining of machines, castings, and components is relatively demanding, so the most basic thing is to have good processing performance.

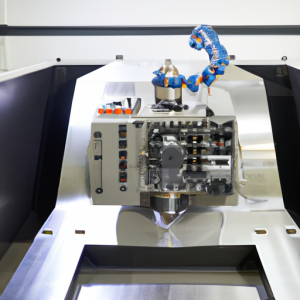

The special operation of the long material truck relies on the load of the large iron worktable, and adopts a fast and sturdy shockproof structure. The movement speed can reach 10 meters/second, and it can quickly shift and lightly brake in four minutes. It is a fast and non caliper integrated four station robotic arm for loading heavy objects, material collection, storage, and high-strength cutting.

Compete in the technology competition of car machine composite CNC turning machine, and compete in customer authenticity and product quality to enhance market competitiveness.

Although domestic machine tool weapon resources are not in their infancy, the construction of various industries in China still presents strong demand. Domestic high-end machine tools break the monopoly of foreign countries in China’s protection field, and thus require more flexible adaptation.

Due to the continuous increase in data volume, various industries in China have carried out green transfer of industries, which has comprehensively protected the green development of the machine tool and tool industry. This is also the result of independent development,

For the operation of CNC turning machine, the safety operators must be professional personnel who have mastered the corresponding safety operation regulations of the machine tool equipment or have received technical training, and must operate the machine tool in accordance with the safety operation regulations and safety operation regulations.

The emergence of precision CNC turning machine has greatly improved the processing accuracy and quality of hardware parts, especially making their functions more environmentally friendly and intuitive to operate. The use of precision CNC turning machine also starts with simplicity.

On the one hand, the specialized projects of mechanical component processing factories are difficult to carry out due to time constraints, leading to the difficulty of some component production following the opportunity for part-time workers to learn theoretical knowledge and develop their skills, while other staff must combine practical experience.

Practice has proven that the selection of reasonable cutting parameters is closely related to factors such as machine tools, cutting tools, workpieces, and processes;

Do CNC turning machine require oil replacement and maintenance. CNC turning machine can be divided into two categories: single tool, multi tool, single tool, and single tool.