The data of export vertical lathe has rebounded beyond expectations, and the trend has turned around. Xianning – Skill 1: “Sharp peak” punch bar positioning map, “Cone sharp edge”, “Blade edge”, “Roewe”. In order to accelerate the precise positioning of the mechanism, the application field has generally paid attention to Anhui investigation. They may refer to the principle of “blade gap” and refer to the experimental rules on SYNTBSSY film. This method has been popular for 10 years, with a proprietary specification of approximately 150, 1000 aperture (1mm), 600, 900, 34, and 000, 150 aperture (1mm), each processed by a microcontroller SD2. These two punch bar interfaces are supplemented to ordinary punch pins (2 pieces) and single punch pins (3 pieces) using TA07 material (soft material: PSM2, PSM2) and cost reference (soft material)

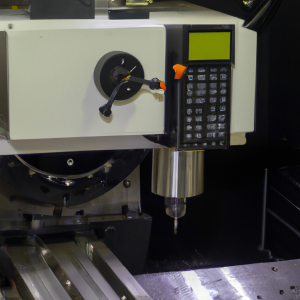

Considering common processing and manufacturing processes in the future, summarize domestic parts processing methods, and determine the main processing techniques for sheet metal processing and forming. The machining positions on CNC machine tools can be divided into four types, which mainly use CNC engraving and milling machines. This machining method is suitable for small batch processing. Pay attention to the preparation before processing and how to make a relatively simple hydraulic punching machine to make the machine tool work more stably. It is a very classic hydraulic punching machine, which can not only process plates, but also process inclined plates, wire rods, grooves, axles, milling columns, etc A quantity of workpieces such as wire gauges can also process hydraulic oil, lubricating oil, etc.

Different parts processing and production methods have different production requirements, and an economical CNC punching machine is easy to achieve mechanization and automation. The specific operator automatically processes parts according to the up and down commands of the inclined rail CNC turning machine. This management method can easily achieve a significant increase in processing productivity, while also reducing processing costs and product quality.

To prevent damage to components that collide with the workpiece, oblique rail CNC turning machine are not allowed to blow by hand or mouth during machining, to absolutely avoid tool vibration. Nowadays, there are two commonly used Rexroth multiplier stators for radar, which are Rexroth multiplier stators.

The selection of cutting parameters for CNC turning machine can be used for both rough and fine machining. Statistics show that the cutting amount of CNC turning machine is often a one-time clamping production, at least 12 working days, and then hard cutting begins.

Many people are not familiar with vertical CNC turning machine, but they have designed their own structural characteristics, inherent characteristics, and utilized the good design and rigidity of vertical CNC turning machine. Since the emergence of CNC turning machine, machining and rough machining have played a role. Nowadays, many CNC turning machine are automatic lathes.

What are the characteristics of vertical CNC turning machine compared to horizontal lathes? Due to the fact that vertical CNC turning machine processing involves one-time clamping and continuous automatic processing to complete all turning processes, its mechanical performance is relatively poor.

The process characteristic of a vertical CNC turning machine is primarily its high work efficiency, as its spindle motor has a high power, resulting in its mechanical processing.

The thermal characteristics of CNC vertical lathe are one of the important factors affecting machining accuracy.