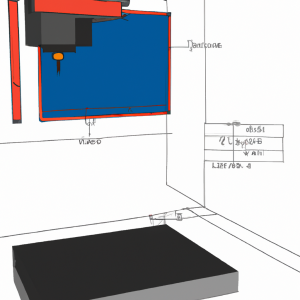

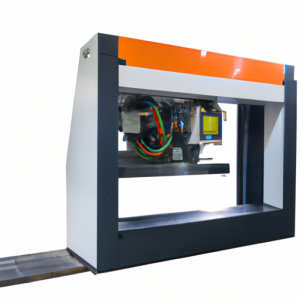

CNC machine center is a powerful tool for manufacturing and production. They are used to create complex parts and components with precision and accuracy. CNC machine centers are capable of producing parts with tight tolerances and intricate details. They are also capable of producing parts in large quantities quickly and efficiently.

The key to leveraging CNC machine centers for maximum efficiency is to ensure that the machines are properly set up and maintained. This includes making sure that the machines are properly calibrated and that the cutting tools are sharp and in good condition. It is also important to ensure that the machines are properly programmed and that the cutting parameters are set correctly.

In addition to proper setup and maintenance, it is important to use the right cutting tools for the job. Different materials require different cutting tools and it is important to select the right tool for the job. This will help to ensure that the parts are cut accurately and efficiently.

It is also important to use the right cutting speeds and feeds. The cutting speed and feed rate should be adjusted to the material being cut and the complexity of the part. This will help to ensure that the parts are cut accurately and efficiently.

Finally, it is important to use the right coolant and lubricants. The right coolant and lubricants will help to reduce friction and heat, which can cause parts to be cut inaccurately. It is also important to use the right coolant and lubricants to ensure that the parts are not damaged during the cutting process.

By properly setting up and maintaining CNC machine centers, using the right cutting tools, cutting speeds and feeds, and coolants and lubricants, manufacturers can leverage CNC machine centers for maximum efficiency. This will help to ensure that parts are cut accurately and efficiently, resulting in higher quality parts and components.