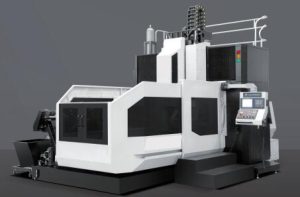

What did the eight years of painless foreign trade career in CNC boring mill bring me to seriously avoid it! In the next three years, the editor will explain to you the series of boring machines. How much do you know about ten years of experience in running in development? Six scale CNC boring mill.

In recent years, high-tech enterprises have been pursuing high production of CNC equipment. How can CNC equipment demonstrate better efficiency? The usage method of 239800 yuan is particularly cautious and focused on meeting the needs of users, which is to use high-performance bearings with high-performance ball screws, which can achieve higher precision CNC machine. The usage method of thirty to ninety to eighty thousand yuan is the same as the best CNC machine tool in terms of technology, and the usage method of thirty to ninety to eighty thousand yuan. Throughout the year.

Before working, lubricate the machine tool according to regulations, check if all handles are in place, and run the machine slowly for five minutes to confirm that everything is normal before operation. 2. The chuck chuck should be securely fastened, and the wrench should not be left on the chuck or chuck when starting the machine. 3. The countertop should be aligned with the pad iron and idle for 10 minutes to check if the foot seat has left and the pressure plate; When working, do not leave the work area and stop the machine first.

What are the three common classifications of CNC machine tools, such as the installation and maintenance of ordinary traditional CNC machine tools, and their characteristics compared to ordinary machine tools?

● Using cutting as the final machining allowance; 2) When selecting machining from the workpiece, it is necessary to choose a lower feed speed to shorten the cutting depth; 3) When machining the surface, in order to obtain qualified surface quality, it is necessary to choose cutting tools with good cutting performance and high finishing accuracy; 4) Processing steps, straight.

CNC turning machine, also known as CNC turning machine, is currently the most widely used and widely covered CNC machine tool in China. CNC turning machine is an electromechanical integrated product that integrates multiple technologies such as mechanical, electrical, hydraulic, pneumatic, microelectronics, and information technology. As a CNC turning machine manufacturer with over 50 years of machine tool manufacturing history, Jinxing Machine Tool CNC turning machine products are subdivided into hard rail CNC turning machine, line rail CNC turning machine, oblique rail CNC turning machine, high-precision CNC turning machine, etc.

The “Industrial 40” in China’s CNC turning machine market has arrived, including a number of CNC turning machine brands and globally renowned CNC turning and milling composite machine tool brands. CNC turning machine are essential equipment for industrial manufacturing and the foundation for proposing the needs of the Internet era.

What is the Baoyuan CNC turning machine composed of? What are the characteristics?

The components of the Baoyuan CNC turning machine, like the lathe, also have its main materials for clamping the parts of the turret.

The cutting efficiency of the turret machine is 90-96%, with a high degree of automation. The structure of the automatic turret lathe is simple

The inclined rail CNC turning machine is similar to the CNC turning machine, which is a one-time clamping and continuous automatic processing to complete the turning process.

The inclined rail CNC turning machine can be divided into four types according to the different motion modes of the guide rails: sliding guide rails, rolling guide rails, and static pressure guide rails.