We are a leading CNC Machine manufacturer, is at the forefront of revolutionizing manufacturing through the integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies. This comprehensive article explores how these advanced tools streamline production processes, enhance precision, and drive innovation in various industries. By incorporating Weish’s expertise in manufacturing, OEM/ODM services, R&D, and design, we demonstrate the transformative power of CNC Machine, CAD, and CAM.

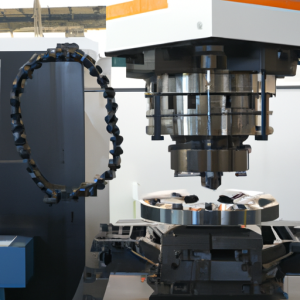

Understanding CNC Machine

CNC (Computer Numerical Control) Machine are automated tools controlled by a computer program to perform precise cutting, drilling, milling, and other machining operations. These Machine are essential in modern manufacturing for their ability to produce high-quality parts with exceptional accuracy and repeatability.

The Role of CAD in Manufacturing

What is CAD?

Computer-Aided Design (CAD) involves using software to create detailed 2D and 3D models of parts and assemblies. CAD software allows engineers and designers to visualize and optimize their designs before manufacturing, ensuring that the final product meets all specifications and requirements.

Benefits of CAD

- Enhanced Design Accuracy

CAD software enables precise and detailed design work, reducing the likelihood of errors and ensuring that parts fit together perfectly in the final assembly. - Improved Collaboration

CAD files can be easily shared and modified, facilitating collaboration among design teams and stakeholders. This collaborative approach speeds up the design process and enhances innovation. - Streamlined R&D

CAD allows for rapid prototyping and testing of new designs, accelerating the R&D process and enabling quicker time-to-market for new products. The Role of CAM in Manufacturing What is CAM?

Computer-Aided Manufacturing (CAM) uses software to control CNC Machine based on the designs created in CAD. CAM software generates the toolpaths and instructions that guide the CNC machine in producing the physical part.

Benefits of CAM

- Increased Production Efficiency

CAM software optimizes the machining process, reducing cycle times and minimizing material waste. This efficiency translates to higher productivity and lower manufacturing costs. - Consistent Quality

By automating the machining process, CAM ensures that each part is produced to the same high standard, maintaining consistent quality across large production runs. - Flexibility in Manufacturing

CAM allows for easy adjustments to the machining process, making it simple to switch between different parts and customize production for OEM/ODM projects. How CNC Machine, CAD, and CAM Work Together

The integration of CNC Machine with CAD and CAM technologies creates a seamless workflow from design to production. Here’s how these technologies complement each other:

- Design Phase

Engineers and designers use CAD software to create detailed models of the parts. These designs are optimized for functionality, aesthetics, and manufacturability. - Programming Phase

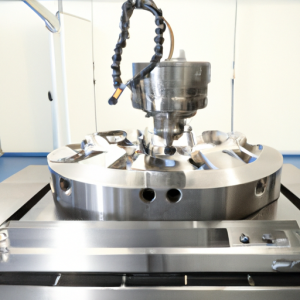

The CAD designs are imported into CAM software, which generates the necessary toolpaths and machine code (G-code). This code instructs the CNC machine on how to produce the part with precise movements and operations. - Manufacturing Phase

The CNC machine, guided by the CAM-generated code, performs the machining operations to create the physical part. The result is a highly accurate and consistent product that meets the original design specifications. Applications of CNC Machine, CAD, and CAM Aerospace Industry

In the aerospace sector, the precision and reliability of CNC Machine, combined with the detailed designs from CAD and the optimized toolpaths from CAM, are crucial for producing high-performance components like turbine blades and structural parts.

Automotive Industry

The automotive industry benefits from these technologies by producing complex engine components, transmission parts, and custom-designed elements with high precision and consistency.

Medical Devices

The medical field relies on CNC Machine, CAD, and CAM to create intricate surgical instruments, implants, and diagnostic equipment with stringent accuracy and quality standards.

Electronics

In electronics manufacturing, these technologies enable the production of small, intricate parts such as connectors, housings, and heat sinks, ensuring precision and reliability.

Why Choose Weish as Your CNC Machine Manufacturer?

- Expertise in Manufacturing

Weish has extensive experience in CNC machining, leveraging CAD and CAM technologies to deliver high-precision parts. Our expertise ensures that every product meets the highest standards of quality and performance.

- Comprehensive OEM/ODM Services

As a leading CNC Machine manufacturer, Weish offers comprehensive OEM/ODM services to meet the specific needs of our clients. We work closely with customers to develop custom solutions that align with their unique requirements.

- Advanced R&D and Design Capabilities

Weish’s dedicated R&D team and advanced design capabilities enable us to push the boundaries of CNC machining technology. We continuously innovate to provide cutting-edge solutions that meet the evolving demands of the market.

- State-of-the-Art Equipment

We utilize state-of-the-art CNC Machine, CAD, and CAM software to ensure the highest levels of precision and efficiency in our manufacturing processes. Our investment in advanced technology allows us to deliver superior quality parts consistently.

- Commitment to Quality

At Weish, quality is our top priority. We implement rigorous quality control measures throughout the manufacturing process to ensure that every part meets stringent standards. Our commitment to excellence guarantees reliable and durable products for our clients.

Conclusion

The integration of CNC Machine with CAD and CAM technologies revolutionizes manufacturing by streamlining production processes, enhancing precision, and driving innovation. As a leading CNC Machine manufacturer, Weish is dedicated to providing high-quality solutions that meet the diverse needs of our clients. With our expertise in manufacturing, OEM/ODM services, R&D, and design, we are well-equipped to deliver custom parts that exceed expectations. Contact us today to learn more about how our advanced CNC machining services can transform your production process.

Tags: CNC Boring Mills,CNC Vertical Lathe,5 Axis Milling Head A/C,Floor Type Boring,Planner Type Boring