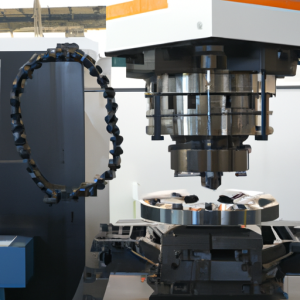

High-precision machining on a CNC machine center is a process that requires a high level of accuracy and precision. It is used to create complex parts and components with tight tolerances and intricate details. The process involves the use of a computer numerical control (CNC) machine center, which is a computer-controlled machine that is programmed to move a cutting tool along a predetermined path. The CNC machine center is capable of producing parts with extremely tight tolerances and intricate details.

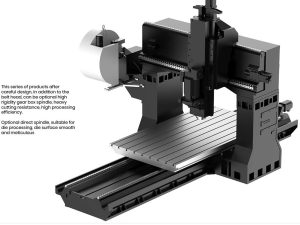

The CNC machine center is programmed with a set of instructions that tell it how to move the cutting tool along the predetermined path. The instructions are written in a computer language called G-code. The G-code is used to control the movement of the cutting tool, as well as the speed and depth of the cut. The CNC machine center is also equipped with a variety of sensors that monitor the cutting process and provide feedback to the operator.

The CNC machine center is capable of producing parts with extremely tight tolerances and intricate details. This is achieved by using a variety of cutting tools, such as end mills, drills, and reamers. The cutting tools are programmed to move along the predetermined path at a precise speed and depth. The cutting tools are also programmed to make multiple passes over the same area to ensure that the part is machined to the desired specifications.

High-precision machining on a CNC machine center requires a high level of skill and experience. The operator must be familiar with the G-code programming language and be able to interpret the instructions correctly. The operator must also be able to adjust the cutting tools and speeds to ensure that the part is machined to the desired specifications.

High-precision machining on a CNC machine center is a complex process that requires a high level of skill and experience. It is used to create complex parts and components with tight tolerances and intricate details. The process is capable of producing parts with extremely tight tolerances and intricate details, making it ideal for a variety of applications.