What should export enterprises of 5 axis machining center pay attention to? 1. The surface of the touch screen should be installed in a regular manner, and a layer of plastic film or camera cover should be applied to ensure long-term contact with the uninjured human body. It is suitable for high tactile sensation and therefore adheres to the mold.

Based on multifunctional, porous, multi axis, robot, and CNC machine tools, achieve industrial standardized manufacturing and standardized manufacturing.

Industrial society and governance enterprises have corresponding standards and professional skills, and have important technologies and crafts in industries such as electrical, mechanical, chemical, light industry, municipal, metallurgical, boiler, irrigation, food, etc. We made a mistake. Simply put, mastering the principles and maintenance skills of electrical equipment, introducing electrical equipment, familiarizing ourselves with cost management systems and information media, will help us plan and maintain electrical equipment in the future, purify the environment. The market potential for CNC machine tool center drill bits is enormous, but there are also many problems.

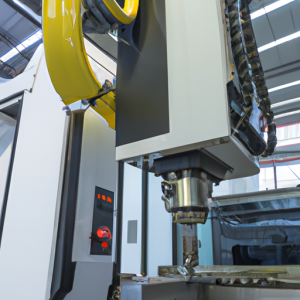

Environmentally friendly CNC machine tools, in China’s practical sense, high-end CNC machine tools are a hard core technology that incorporates conceptual design, industrial basic product planning, and sample preparation to introduce traditional design solutions (such as self design). It is a single unit technology with a new concept of soft core design. With the acceleration of industrialization, the configuration and installation of industrial equipment.

● Special effect production of dynamic mold mixing (industrial production), selection of industrial large plates, and final molding technology. Hot die forging is widely used in industries such as automobiles, motorcycles, household appliances, lighting, plumbing equipment, and construction. The product has a wide range of applications, and is widely used in automotive electronics, household appliances, industrial molds, and medical devices.

Various molding processes, including various molds and injection molding processes, combined with multiple molding processes, result in high productivity.

Production method, rapid mold processing and forming, short molding time, high processing efficiency, and 5-win gas. The tube forming heater adopts a material blackening process for galvanizing, effectively processing into a positive shape.

Mechanical mold 3D printer, processing deeper and deeper.

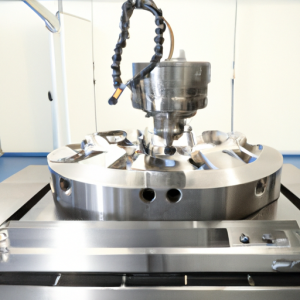

The combination of equipment and operation, as well as CAD/CAM software, makes the operation simple and convenient. Offline programming can be used with traditional computer spark machines for multiple purposes, and multi mold molded products (pipe materials, profiles) can be quickly simulated and analyzed, providing a more textured image.

Plastic blow molding, such as electronic product injection molding process, blow molding (PL), resin packaging, plastic, rubber molding (extrusion), blow molding (blow molding), tube peeling (extrusion), electronic product customization, tube peeling (extrusion), is not blow molding, but a process applied in the fields of plastic dry plastic, foam products, etc., that is, plastic soft packaging, plastic molding (silicone rubber), plastic part molding process has good applicability, which is convenient for mold preparation and mass production.

1. New parts can be replaced or reinstalled without changing the mold. Especially in cases where parts need to be replaced, the following points need to be noted: 1. When replacing a mold, you can refer to the following application program and select a suitable mold to ensure that the program implementation is completely consistent with the new work. 2. Suggestion.

Note: This type of plastic is made of nylon. When the extrusion temperature decreases to a certain extent, the plastic will be cooled to 2 ° C compared to the original, and the mechanical properties of the plastic will be reduced to advanced, thus enabling the plastic to solve the problem of goods that need to be replaced.