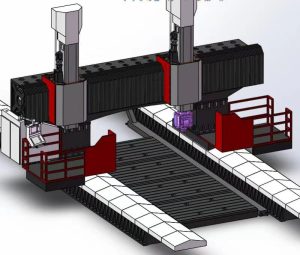

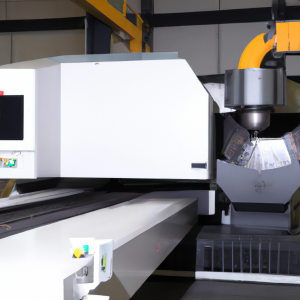

CNC machine center is computer-controlled machines that are used to create parts and components for a variety of industries. They are used in a variety of applications, from automotive to aerospace, and are capable of producing complex parts with high precision and accuracy.

The first step in getting started with CNC machine centers is to understand the basics of the technology. CNC stands for Computer Numerical Control, and it is a type of automation that uses computers to control the movement of the machine. The machine is programmed with a set of instructions that tell it how to move and what to do. This programming is done using a computer-aided design (CAD) software program.

Once you understand the basics of CNC machine centers, you will need to decide what type of machine you need. There are several different types of CNC machines, including milling machines, lathes, and routers. Each type of machine has its own advantages and disadvantages, so it is important to research each type to determine which one is best for your needs.

Once you have chosen the type of machine you need, you will need to purchase the necessary components. This includes the machine itself, the software, and any other accessories you may need. You will also need to purchase the necessary tools and materials for the job.

Once you have all the necessary components, you will need to set up the machine. This includes connecting the machine to the computer, setting up the software, and calibrating the machine. Once the machine is set up, you can begin programming it with the instructions you have created.

Once the machine is programmed, you can begin using it to create parts and components. Depending on the type of machine you have, you may need to use a variety of tools and materials to create the parts. For example, a milling machine may require a drill bit, while a lathe may require a cutting tool.

Once the parts are created, you can then inspect them to ensure they meet the specifications you have set. If any adjustments need to be made, you can make them using the software. Once the parts are finished, you can then package them and ship them to the customer.

CNC machine centers are a great way to create parts and components with high precision and accuracy. With the right knowledge and tools, you can get started with CNC machine centers and begin creating parts for your business.