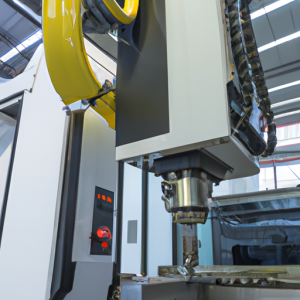

Exploring the Benefits of CNC Machine Center Solutions for Unparalleled Precision and Efficiency

CNC machine centers are a powerful tool for achieving unparalleled precision and efficiency in manufacturing. By utilizing computer numerical control (CNC) technology, these machines can be programmed to perform complex operations with a high degree of accuracy and repeatability. This makes them ideal for a wide range of applications, from prototyping to mass production.

Compared to traditional machining methods, CNC machine centers offer a number of advantages. For starters, they are capable of producing parts with a much higher degree of accuracy and repeatability. This is due to the fact that the machine is programmed to follow a precise set of instructions, eliminating the possibility of human error. Additionally, CNC machines are able to produce parts with a much higher level of complexity than traditional machining methods. This allows for the production of parts with intricate shapes and features that would be impossible to achieve with manual machining.

Another benefit of CNC machine centers is their ability to reduce production time. By utilizing computer-controlled processes, CNC machines can produce parts much faster than traditional machining methods. This can significantly reduce the amount of time required to complete a project, allowing for faster turnaround times and increased productivity.

Finally, CNC machine centers are also much more cost-effective than traditional machining methods. By eliminating the need for manual labor, CNC machines can reduce labor costs and increase efficiency. Additionally, CNC machines require less maintenance than traditional machining methods, resulting in lower maintenance costs.

Overall, CNC machine centers offer a number of benefits that make them an ideal choice for a wide range of applications. By providing unparalleled precision and efficiency, CNC machines can help to reduce production time and costs while increasing productivity. As such, they are an invaluable tool for any manufacturing operation.

How CNC Machine Center Solutions Can Help Streamline Your Manufacturing Processes for Maximum Efficiency

CNC machine centers are a powerful tool for streamlining manufacturing processes and increasing efficiency. By automating the production process, CNC machine centers can reduce labor costs, improve accuracy, and increase production speed.

Compared to manual production processes, CNC machine centers offer a number of advantages. For example, CNC machines can be programmed to produce parts with a high degree of accuracy and repeatability. This eliminates the need for manual inspection and rework, resulting in fewer errors and faster production times. Additionally, CNC machines can be programmed to produce parts with complex geometries, which can be difficult or impossible to achieve with manual processes.

CNC machine centers also offer a number of other benefits. For example, they can be used to produce parts with a wide range of materials, including metals, plastics, and composites. This allows manufacturers to produce parts with a variety of properties, such as strength, flexibility, and durability. Additionally, CNC machines can be programmed to produce parts with a variety of finishes, such as anodizing, plating, and painting. This allows manufacturers to customize their products to meet customer needs.

Finally, CNC machine centers can be used to produce parts in large quantities. This allows manufacturers to reduce costs by producing parts in bulk, rather than producing them one at a time. Additionally, CNC machines can be programmed to produce parts with a variety of shapes and sizes, allowing manufacturers to produce parts that are tailored to their customers’ needs.

Overall, CNC machine centers offer a number of advantages that can help streamline manufacturing processes and increase efficiency. By automating the production process, CNC machines can reduce labor costs, improve accuracy, and increase production speed. Additionally, CNC machines can be used to produce parts with a wide range of materials, finishes, and shapes, allowing manufacturers to customize their products to meet customer needs. Finally, CNC machines can be used to produce parts in large quantities, allowing manufacturers to reduce costs by producing parts in bulk. By taking advantage of these benefits, manufacturers can maximize efficiency and reduce costs.