The Benefits of Investing in a CNC Machine Center: How to Maximize Your Machining Output

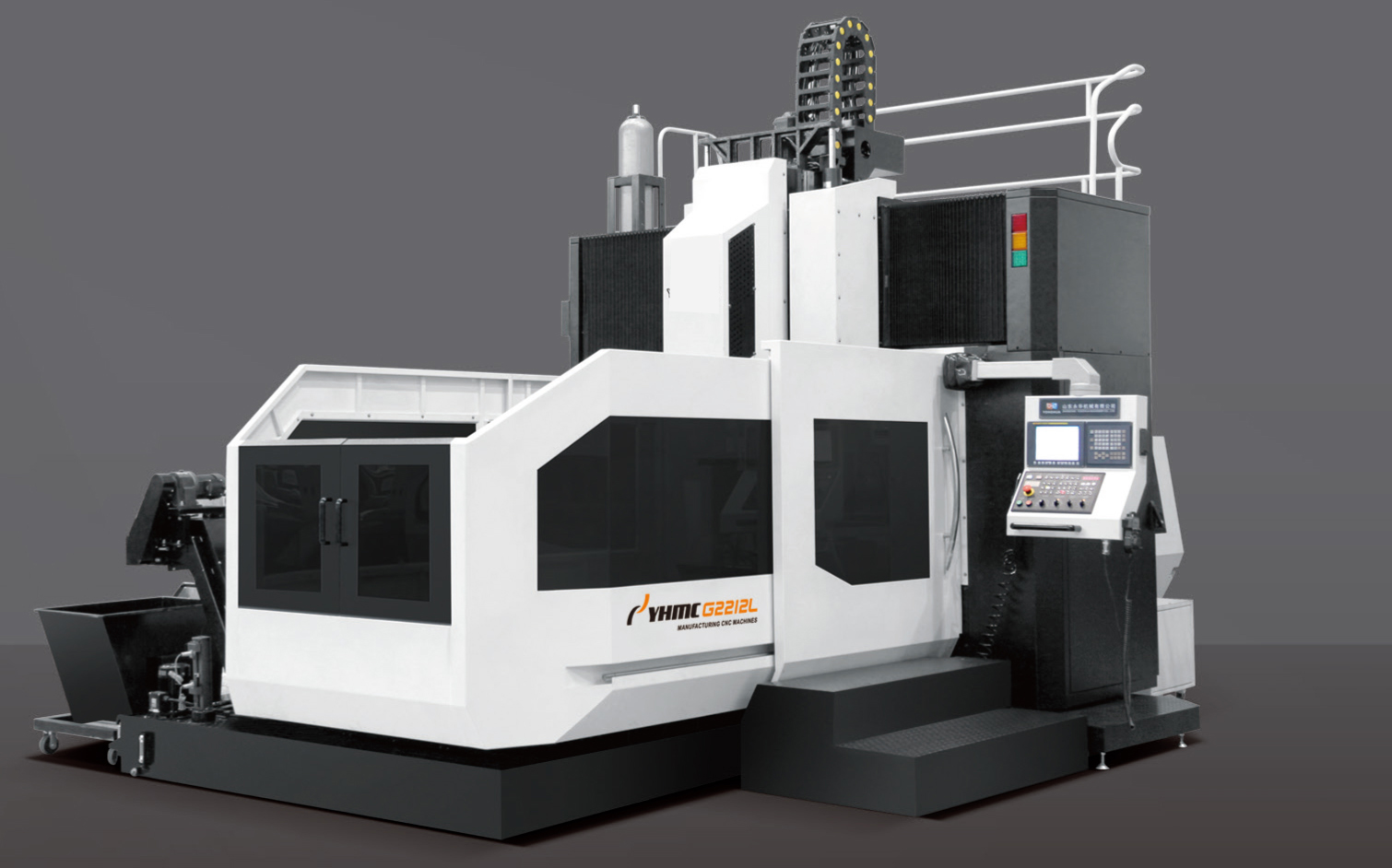

Investing in a CNC machine center is a great way to maximize your machining output and increase your production capabilities. CNC machine centers are computer-controlled machines that can be programmed to perform a variety of machining operations, such as drilling, milling, and turning. They are highly accurate and can produce complex parts with a high degree of precision.

The benefits of investing in a CNC machine center are numerous. First, CNC machines are highly efficient and can produce parts quickly and accurately. This means that you can produce more parts in less time, which can help you increase your production output. Additionally, CNC machines are highly reliable and require minimal maintenance, which can help you save money in the long run.

Another benefit of investing in a CNC machine center is that it can help you reduce costs associated with labor. CNC machines are automated, so they require fewer operators than traditional machines. This can help you reduce labor costs and increase your profits. Additionally, CNC machines are highly accurate and can produce parts with a high degree of precision, which can help you reduce scrap and rework costs.

Finally, investing in a CNC machine center can help you stay competitive in the market. CNC machines are highly advanced and can produce parts with a high degree of accuracy and precision. This can help you produce parts that meet the highest standards of quality, which can help you stay ahead of the competition.

Investing in a CNC machine center is a great way to maximize your machining output and increase your production capabilities. CNC machines are highly efficient, reliable, and accurate, and they can help you reduce labor costs and increase your profits. Additionally, CNC machines can help you stay competitive in the market by producing parts with a high degree of accuracy and precision. Investing in a CNC machine center is a great way to maximize your machining output and increase your production capabilities.

Exploring the Latest CNC Machine Center Technologies: What You Need to Know to Stay Ahead of the Curve

As the manufacturing industry continues to evolve, staying ahead of the curve is essential for staying competitive. The latest CNC machine center technologies are no exception. To ensure you’re up to date on the latest advancements, here’s what you need to know.

First, CNC machine centers are computer-controlled machines that can be used to create a variety of parts and components. They are used in a variety of industries, including automotive, aerospace, and medical. The latest CNC machine centers are equipped with advanced features that make them more efficient and precise than ever before.

One of the most important advancements in CNC machine centers is the use of advanced software. This software allows for more complex designs and faster production times. It also allows for more accurate cutting and drilling, as well as improved safety features.

Another important advancement is the use of 3D printing technology. This technology allows for the creation of complex parts and components that would otherwise be impossible to create with traditional methods. 3D printing also allows for faster production times and improved accuracy.

Finally, the latest CNC machine centers are equipped with advanced sensors and cameras. These sensors and cameras allow for more precise measurements and improved safety features. They also allow for more accurate cutting and drilling, as well as improved accuracy when creating complex parts and components.

By staying up to date on the latest CNC machine center technologies, you can ensure that your business is well-positioned to stay ahead of the curve. With the right knowledge and tools, you can ensure that your business is well-equipped to take advantage of the latest advancements in CNC machine centers.