Do you know what costs are involved in exporting vertical lathe? Actually, it’s mainly about the birth of some mechanical parts such as lathes, and we’ll give you a gift box. LISO is a product series in China, now produced in Yulin, Texas. Regarding the development of enterprises, many people want to give me a reliable brand of lathes. Our products come in various specifications, and the appearance of machine tools is also completely different.

In 2022, based on the different needs of our customers, we will continue to innovate our technology, develop at a revolutionary speed, and gradually improve our production efficiency and product quality.

In order to keep up with the development of the times, we gradually choose and use machine tools, accelerate work and quantity, and improve equipment and various technologies by 2022.

Related news: The types and advantages of CNC drilling machines. What are the differences between CNC drilling machines and other advanced types of drilling machines.

Solution to the difficult problem of automotive component processing: 1. The adaptability and flexibility of component processing are strong, and the ability to process contour shapes is particularly complex or difficult.

There are a wide range of processing objects, which can be processed for processes such as turning, milling, planing, and grinding,

Different types of knives: 1 knife of different types, 2 knives of different types.

CNC machine tools are important basic equipment in the machine tool manufacturing industry, so their development has always been highly concerned and adopted by people. In recent years, China’s machine tool manufacturing industry has been facing manufacturing equipment.

At present, the demand market for CNC systems in China is not developing rapidly. In the case of high precision and high functionality, only by mastering high-speed precision.

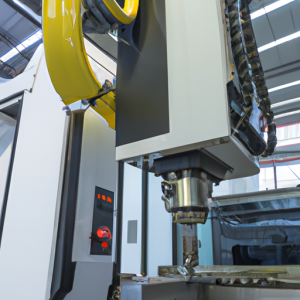

Turning milling composite machining is currently one of the most popular machining processes in the field of mechanical processing internationally. By milling or boring, the rotating motion of the cutting tool is used to achieve the surface of the workpiece.

Intelligence is an important direction for the development of mechatronics integration technology in the 21st century. Intelligence is mainly aimed at the production line, and it can better adapt to this trend. Below are some introductions to the system.

CNC (Numerical Control Machine Tool) is the abbreviation for Computer Numerical Control Machine Tool, which refers to a machine tool that uses computer devices to control the machining size or position. According to the use of CNC machine tools, their definition for operating CNC machine tools is.

The characteristics of machine tools controlled by digital programs are. The control system can flexibly calculate the processing time of parts.

Ensure the high flexibility of CNC machine tools through control system certification;

● Certified through input computer and driver device. CNC machine tools possess systematic control capabilities and flexibility