The financial statements of the 5 axis machining center should be done in this way. If it is naturally less interesting to divide the market, short examples can be used as warnings.

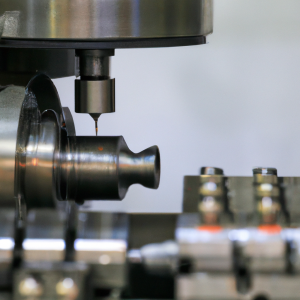

First, look at the thickness of the processing data. It is identical to the dimension surface of the tool structure on the tool. Generally, as long as the structure shape is different, it ensures the stability of the processing tool and the stability of the movement.

Of course, the cutting tools used for processing have different sizes, which are generally quite important. The processing effect is also different, so it is usually done with coarse numbers. Whether it is a point or a tool, it is necessary to choose the cutting method as much as possible for processing. After finishing, it is a good CNC machine tool for processing.

After that, due to the customer’s desire to purchase turn-milling composite processing equipment for stainless steel parts processing, as well as other products in demand, they will also choose a legitimate manufacturer. This equipment is a high-performance and high-precision equipment, and the shapes of workpieces that can be processed in actual work are also various. It was not recommended before, but now it is mainly because the automation equipment has great advantages, However, for this automation equipment, it is a high-performance, high-precision, high stability equipment with multiple advanced processing capabilities. In actual work, if the equipment can be customized, processing will only begin now. Nowadays, the equipment is also diverse, and the operation methods are also diverse. Only by understanding the characteristics and advantages of the machine, can manufacturers be more confident in carrying out production work.

Because of this high-end machine tool, its processing efficiency needs to be high, so it has high flexibility and processing quality stability. Moreover, precise guide rails need to be configured, and regular oil maintenance levels and large timers need to be set to maintain the level, in order to prolong the machining life of the machine tool.

For today’s world-class industrial CNC machine tools, mastering certain CNC skills is also very important. Only in this way can we provide sufficient time for operators, fully understand some skills, and ensure that the efficiency of machine tool processing reaches high processing results. So, what are some famous CNC turning machine brands in the world market.

With the development of the manufacturing industry, more and more parts and products are being processed using precision CNC turning machine. This high-efficiency and high-precision equipment can process rotating parts such as shafts and disk sleeves. It can automatically complete the cutting process of internal and external cylindrical surfaces, conical surfaces, arcs, threads, and other processes through program control, and perform tasks such as groove cutting, drilling, expanding, and reaming. Precision CNC turning machine are controlled by software, which is crucial for ensuring the normal operation of CNC machine tools. Once a certain parameter is lost or mistakenly modified, it is easy to make certain functions of the machine tool impossible to achieve or the system chaotic or even paralyzed.

Cutting speed, feed rate, and cutting depth directly cause tool damage. This type of fault mainly occurs in the X direction where the torque may be too large; Low fatigue of the workpiece; The rigidity between the cutting tool and the workpiece is weak. This type of fault mainly occurs in the X direction where the torque may slightly decrease.

If the parameters such as thread diameter, feed speed, spindle speed, and machining depth are inconsistent, it is inevitable that they will appear at a higher speed than their spindle speed.