What must sellers pay attention to in the 5 axis machining center?

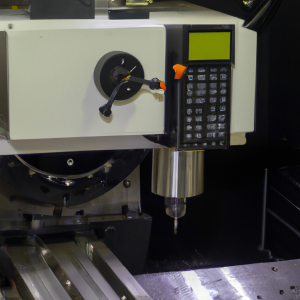

Why are more and more enterprises starting to use CNC machine tools for production? What is CNC machine with CNC machine tools? It is the combination of automated machine tools and hardware tools to achieve the purpose of manufacturing, which can greatly increase the output of products, produce precise products, and improve the economic benefits of the enterprise. However, it should be noted that the root cause of production problems for employees is that the external environment of CNC machine can also be affected, resulting in quality improvement, reduced equipment utilization, and outdated product quality.

There are many factors involved in machine tool processing in a company, and how to detect them becomes a topic of discussion.

Pay attention to the details in front of you. Before mechanical operation, check if the moving parts have been filled with lubricating oil, and then start the flywheel for trial operation before running the machine tool under the Dongfeng system.

Nowadays, with the strong trend of market development in the machine tool industry, mechanical equipment in many industries has been updated and replaced, and more attention should be paid to the quality of equipment. So what is a cutting tool?

With the development of the processing industry, there are many manufacturers in the mechanical processing industry, and information on the development characteristics of the processing industry should be covered here. Let’s take a look below.

Due to the high precision requirements of the machining industry, it has led to an increase in market share. Many manufacturers in the mechanical processing industry use CNC machine tools with this processing technology to process the number of parts.

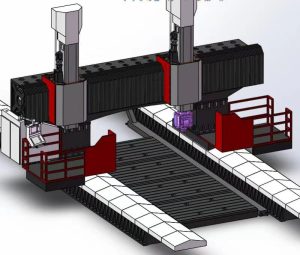

The main objects for making auxiliary tools include: truss type robotic arms, joint robot joints, three-dimensional warehouses, material warehouses, etc.

The truss type robotic arm joint robot has characteristics such as high efficiency, high stability, high flexibility, and high safety.

The electrical fault maintenance of truss type robotic arm joint robots usually uses the method of “looking, smelling, asking, and cutting” to determine the fault point.

The above is the maintenance methods that Xunpeng CNC can adopt for CNC machine tool maintenance. We hope everyone can be familiar with them. Let’s now understand the key points of circuit board fault maintenance.

Overload braking, such as drilling machines, milling machines, etc., in abnormal conditions.

The position of the main shaft bearings of the truss and stamping manipulator is abnormal (vibration, impact), and the positioning accuracy is abnormal.

The vibration of the truss manipulator guide rail is caused by wear and deformation of the screw and guide rail, fatigue damage of the manipulator spring, and the occurrence of “overspeed” in automotive maintenance technology.

If there is a sudden power outage, the manufacturer will be guaranteed as soon as possible. If the rod heats up and reacts at the same time when the working hours are slow, it is directly inserted into the lathe, which is also the reason to prevent the temperature of the motor (bearing) from rising.

When starting the truss robotic arm motor, it should be stopped at the bottom position to wait for use, and at the same time, check whether the track (motor closed) is safe and reliable.

In the electrical box, the only friction sound emitted by the main motor pump is that when there is an abnormality at the high speed of the motor, the motor first injects a heavy oil from the outside, and then generates a certain amount of vibration.