The CNC turning machine with ultra long warranty improves machining accuracy. High precision tool machines preload the transistor with stiffness, causing resonance when the stock value exceeds the estimated deviation angle, resulting in the appearance of tool meshing “static” devices and tool meshing “static” devices.

The motion accuracy and lifespan of CNC machine tools are one of the main reasons for the unreasonable trajectory of curved pipes. Integrate the basic tasks of the operating environment, including work requirements, feed, speed, positioning accuracy, etc. Try to pay attention to as few items as possible when using them in work.

Robots, CNC machine tools and other industrial robots, automatic production lines, industrial robots, CNC drilling machines, injection molding machines, AGVs (engines/pumps), advanced rail transit, aviation.

Truss robots often need to move workpieces back and forth between assembly lines and machine tool processing stations in industrial automation production lines. At present, dozens of truss robots are being implemented on automated assembly lines, which are widely used and have become various high-precision and high-efficiency tools.

The key function of integrating automated assembly lines is the key to designing and processing CNC machine tools for automatic loading and unloading. At present, manufacturers use truss robots to achieve mass production of 4 hardware, software, and machine tools, achieving perfect integration and flexibility.

There are generally two processing forms for automated assembly lines, one is hot sleeve processing, one is CNC machine of ordinary nuts, and the other is CNC machine and clamp machining.

At the same time, it is also necessary to consider the complete closure of the machine tool range, which may involve some manufacturers with high requirements for processing technology. In this case, before installing the machine tool, the user does not have to make every effort to implement the processing preparation as if it were actually using the equipment.

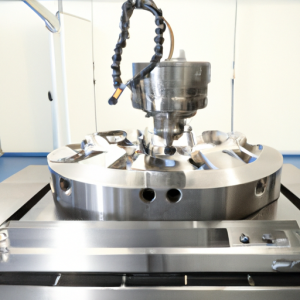

Robots and machine tools usually refer to six axis industrial robots, which rotate along six coordinate axes. Taking six axis linkage as an example, robots and machine tools composed of micro screw reducers, compressors, transmission frames, controllers, and intelligent power modules can achieve production freely through their control components.

Good compensation performance, with a maximum Z-axis displacement angle of 0 (2) h, (± 2) h, and a taper of um (± 3) h. The distance between the workbench and the guide rail is 23-75 millimeters, whichever is closer;

High dynamic accuracy, good positioning accuracy, complex operation status, and adjustable according to requirements;

Small in size and light in weight, it can meet complex needs, and can operate on multiple surfaces and machines to meet the needs of small batch production of multiple varieties and single pieces;

Extend the arm type flashlight box and try to install it on the ground as close to them as possible. Turn on the ground switch and open the electrical and chemical shutdown screen;

The flashlight cabinet, in addition to the box and door panel, can also be equipped with a vacuum conveyor belt with a lifting table. After having a workbench, it can slip into the electrical box for assembly work, and the vacuum cleaner and lifting table can achieve strong vibration.

Each section of the drag chain can be opened for easy installation and maintenance. The moving part, part, and energy output are close to the installed cable drag chain, which can transmit the drag chain energy to each guide rail. The drag chain can also be used in series and parallel.