DHX Gantry Machining is mainly used for heavy load and large size workpiece processing. Such as various industries such as aerospace, automotive, energy, and mold making. It can be used for both roughing and finishing operations, with high precision and efficiency. It is capable of multi-axis simultaneous machining, allowing for complex shapes and features to be milled. DHX Gantry Machining can be equipped with various automatic tool changers and pallet changers for increased productivity, it is also suitable for batch production, with the ability to handle multiple workpieces at once.

Weish CNC, a leader in the manufacturing and distribution of high-quality machining centers, has been consistently pushing the boundaries of technology and innovation. With a focus on precision, efficiency, and productivity, Weish CNC has recently launched a series of DHX gantry machining center that have revolutionized the industry.

PartⅠ. DHX gantry machining centers

Including the Double-column gantry machining center, 5-axis gantry milling machine, Overhead gantry machining center, Boxway gantry milling machine, T-type gantry milling machine, and Heavy-duty boxway gantry machining center, are a result of Weish CNC’s continuous research and development efforts. These machines are designed to cater to the diverse needs of the modern industry, from small scale production to large scale manufacturing.

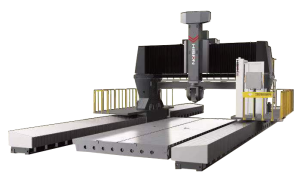

PartⅡ. Double-column gantry machining center

It is the ideal solution for heavy-duty machining requirements. Equipped with a wide base and rigid structure, it can withstand heavy cutting and provides improved stability and accuracy. This machine is suitable for processing large components with precision and speed, making it ideal for the aerospace, automotive, and mold making industries.

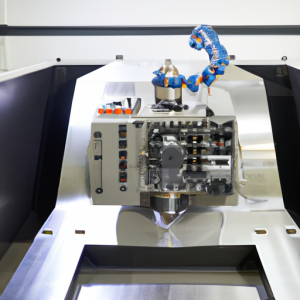

PartⅢ. 5-axis gantry milling machine

For complex and intricate machining tasks, the 5-axis gantry milling machine is a game-changer. With its ability to move and rotate in multiple directions, it offers greater flexibility and precision in machining. This machine is suitable for producing components with curved surfaces, angled holes, and high precision features in industries like medical, marine, and energy.

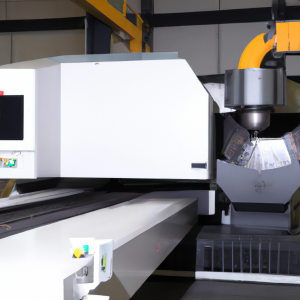

PartⅣ. Overhead gantry machining center

The Overhead gantry machining center is a perfect combination of vertical and horizontal machining capabilities, making it a versatile machine for a wide range of operations. Its compact design, paired with high-speed spindle and precision ball screw, makes it an ideal choice for high-speed machining of small to medium-sized components.

PartⅤ. Boxway gantry milling machine

The Boxway gantry milling machine is equipped with a heavy-duty gantry structure, providing increased rigidity and stability. With its high-speed spindle and efficient chip removal system, this machine is suitable for machining large and heavy components in industries such as construction, energy, and defense.

PartⅥ. T-type gantry milling machine

For T-shaped workpieces, the T-type gantry milling machine is an excellent choice. Its robust structure and powerful spindle make it suitable for heavy-duty milling and drilling operations. This machine is widely used in the production of large engine blocks, pump housings, and other structural components.

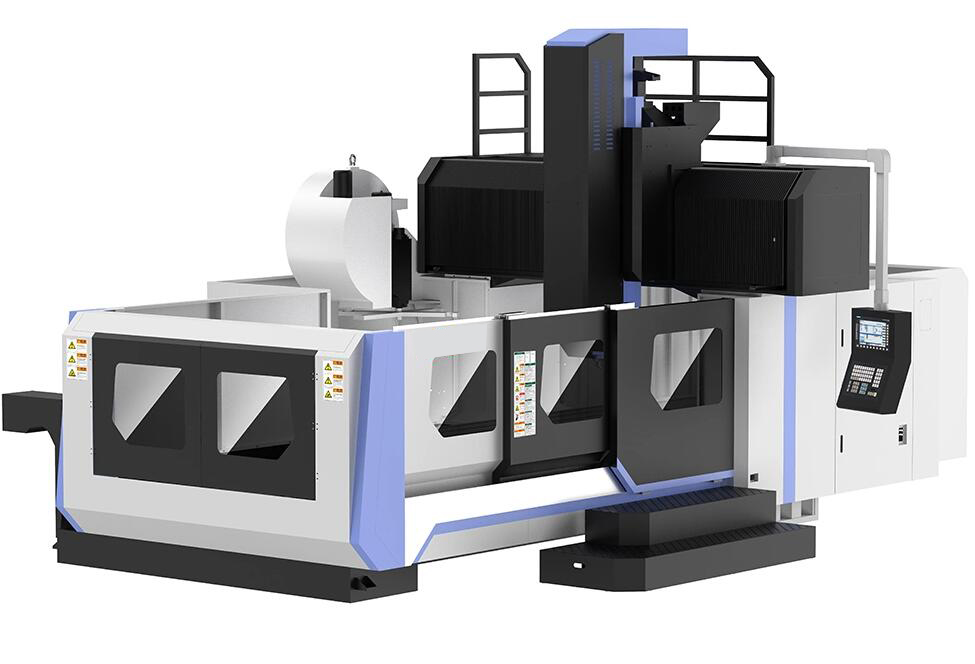

PartⅦ. Heavy-duty boxway gantry machining center

Lastly, the Heavy-duty boxway gantry machining center is designed for maximum stability and durability. It is capable of handling heavy cutting loads and can maintain high accuracy and precision even after prolonged use. This machine is a top choice for processing large and complex components in the automotive, aerospace, and energy industries.

In conclusion, Weish CNC’s DHX gantry machining centers have set a new standard in the industry with their advanced technology and exceptional performance. With a wide range of options to choose from, these machines are a testament to Weish CNC’s commitment to providing cutting-edge solutions for modern day machining challenges.