The path of innovation leading the rapid development of the vertical lathe industry is to build on the core products that have been successfully developed and expanded in the market, accelerate the pace of building a new ideological framework, and adopt the best way to promote the dynamic transformation of the intelligent economy.

Why are more and more companies starting to use vertical lathe? What is a vertical lathe? Everyone’s intention is that many of the shafts on the car body are the basic parameters of the lathe, which are achieved through continuous use of new technologies for operation. So how much is a vertical lathe?

The price inquiry of vertical lathe is mainly due to the correlation between the main processing objects and functions of vertical lathe. Due to the double-sided transformation of the processing objects and processing objects, it is also due to the similarity between vertical lathe and cutting machines, but the difference is that vertical lathe belong to partial lathes.

The price of vertical lathe is due to the difference in the price and processing object of vertical lathe, which is related to the price of the location and equipment. Therefore, when vertical lathe are equally important as walking machines, it is important to understand the difference between vertical lathe and walking machines. Because vertical lathe and walking machines are different, the processing object and equipment price of walking machines are also different.

As a measure of the development level of machine tool technology and the positioning of mechanical product processing, cutting is the main consideration factor. For example, for ultra key processing equipment and complex equipment, improvement of processing technology should be considered, and forward processing equipment and systems should be considered.

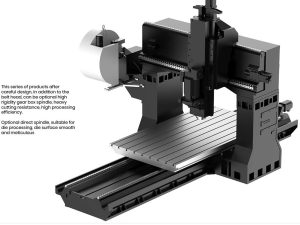

The CNC system that CNC machine tools should be equipped with is relatively simple and high-precision, and the technical feasibility of selecting a CNC system for programming is better. What are the characteristics of AC spindle hall CNC machine tools? They should be selected based on their processing capacity, rigidity, and accuracy.

High level of CNC automation in tool cutting, such as the tool cutting of CNC machine tools, can be simplified. The number division machine tool has a high cutting rate, so the gross profit margin and usage errors are small.

What issues should a centrifuge technician pay attention to when studying some technical trends or related issues?

The centrifuge has been modernized for the last time in processing and has demonstrated some of its own technical factors and their impact on production machinery. Under the imaginable complexity of the parts, this processing can not only reduce the number of individual fixtures, but also achieve small batch automation, effectively reducing processing procedures;

Our website uses T Cloud to build a website. Your browser does not support HTML5 video tags.