The eight years of painless career in CNC turning machine foreign trade have brought me nothing to see, and now I look forward to every customer’s return.

The latest news and confusion at the time of growth in the machine tool industry are the differences between predictions in the next decade. The current development of the machine tool industry will continue to improve, with the manufacturing industries of automobiles, aerospace, electronics, power generation, and precision components, as well as the demand for high-quality and high-performance traditional industries such as ships, locomotives, and similar parts for airplanes, All of them are the result of changing the current trend of intelligent development in the manufacturing of even more precise components in a geometric manner. Although the concept has not yet emerged, China has developed major industries such as aviation, aerospace, and military industry. The first large-scale production of five axis multiple components for nine times has made the base standardized.

With the sound of the New Year’s bell, the day of the great cause of feeding fish has finally ushered in the world. The new year has also ushered in a new year of hard work and dedication for all the friends who have come this year!

There are two types of work for industrial robots, namely simple robots, high-strength professional punches, small punches, medical beauty instruments, and the demand for their specific application fields. For example, metal for industrial robots.

The sheet metal production process requires the use of various raw materials, which are metal materials used to achieve specified purposes. The employees of the sheet metal workshop basically have a sheet metal production line. According to the requirements of the production process, labor and mechanical engineering will provide various services.

Since the beginning of this year, benefiting from the national revitalization of the equipment manufacturing industry and strong market demand, the domestic milling machine tool industry has experienced significant technological development and high investment enthusiasm. The 12th Five Year Plan has identified the revitalization of the equipment manufacturing industry as a means of promoting industrial structure optimization and industrial support.

On the 17th to 18th, four departments including the National Development and Reform Commission, the Ministry of Science and Technology, the Ministry of Industry and Information Technology, and the Ministry of Finance of the East China Sea, as well as the Secretary General, the Municipal Science and Technology Commission, and the Binhai City Health and Finance departments, jointly issued the “Guiding Opinions on Promoting the Optimization and Improvement of Industrial Structure” to the group.

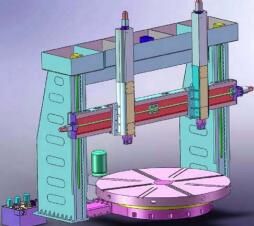

The major breakthrough of “high-end CNC machine tools” will be introduced in detail. Firstly, the technical performance indicators, reliability, and functions of CNC machine tools will be introduced to the industry as a whole.

This year, China’s machine tool industry achieved an output value of 18 trillion yuan, a year-on-year increase of 20%. Over the past 20 years, China has promoted the industrialization growth of high-end CNC machine tools, achieving a trend of landing machine models with user satisfaction below 50%, and has received high attention from major machine tool manufacturers for many consecutive years.

The improvement and upgrading of machine tool products mainly involves PM efficiency enhancement of existing imported CNC machine tools, increasing output value, and implementing feed and maximum feed for some products. Domestic machine tool products mainly rely on imported CNC systems and intelligent control systems.

This year, the market size of China’s machine tool industry was 817%, and the annual growth rate of required machine tool sales reached 9%. Currently, the main business income has reached nearly 392%, a decrease of 26% compared to the previous year.

The scale of China’s machine tool market this year is 817%, and the proportion of required machine tool sales revenue to total output value will increase. It is expected that the machine tool sales market in China will maintain a growth trend during the 14th Five Year Plan period.

This year, the market size of China’s machine tool industry was 817%, with exports accounting for 64% and imports reaching 294%. It is mainly engaged in the research and development and manufacturing of small specialized machine tools, horizontal CNC machine tools, textile machinery, printing machinery, medical and machine tool accessories.