WEISH CNC MASTER is a national high-tech enterprise which integrates R&D, production, sales and maintenance, and has its own import and export rights.Since the establishment of the company, strictly to science and technology as the leading, market-oriented, quality as the fundamental, as a guarantee to the concept of service, has obtained the considerable development.

Many of the products and technology of a domestic first-class, powerful and enhance the core competitiveness of enterprises. Products are exported to South America, Africa, Middle East, Southeast Asia and other countries, by the praise and trust of users.

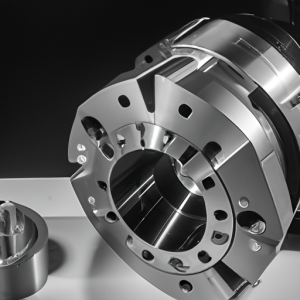

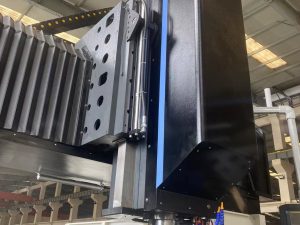

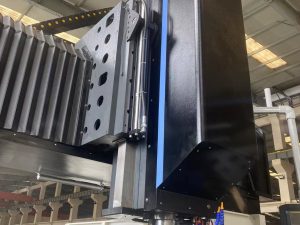

Weish 3 axis cnc machine is a tool designed for automated, efficient and accurate production of components. It is computer-controlled and can carry out complex tasks with precision and accuracy. This technology has been adopted by various industries including aerospace, defense, automotive, and medical, to reduce cost and increase production efficiency. It is capable of cutting intricate patterns and shapes with great accuracy while reducing material waste, making it an ideal choice for mass production.

Weish 3 axis cnc machine is a computer-controlled machine tool that is designed to efficiently and accurately fabricate complex components. It is used in the manufacturing of components across a wide range of industries, from aerospace and automotive to medical and telecommunications. The machine’s extremely precise cutting capabilities enable manufacturers to produce components of the highest quality, often at a fraction of the cost using traditional methods.

Why choose us?

- 1Weish CNC commitment is to support our customers who purchase any of our machine and gives very quick reaction of any problems happened to the machineWeish Machines has a after sales service of conventional machinery with a national and international quality service that has the seal of the prestigious company TÜV Rheinland. Our commitment is to offer the best customer service from day one.

3 axis cnc machine–A Guide to Frequently Asked Questions

2.How does the portal milling machine center ensure the safety of operators?

3.Development status of 3 axis cnc machine industry

4.Portal milling machine manufacturer service and quality system

5.What are the after-sales services available for gantry milling machine?

6.Does the 3 axis cnc machine have remote monitoring and diagnostic capabilities?

7.What is CNC Portal milling machine and how does it work?

8.What is the production capacity of the factory for cnc gantry milling machine?

9.Can the processing capacity of the gantry milling machine be expanded or customized?

1.What are the maintenance requirements for the gantry milling machine

1. External maintenance: Maintain the internal and external surfaces of the machine tool. When changing products for processing, clean the work surface as appropriate, and check and repair burrs at any time.

2. Keep the spindle and tool magazine clean. Check the tool magazine when turning on the machine. The spindle needs to run at low speed for 10 minutes before starting work.

3. Knife handles and knife sheaths are neatly arranged and rust-proof. Check that the screws should not be loose or rough.

4. Keep the appearance of the computer clean and dust-free. Clean up junk files and organize folders at any time. File naming must include information such as (name, version, time, operator).

5. Keep the electric control box clean and dust-free.

6. Lubricating oil Check the oil level in the oil pool, which requires the lubricating mechanism to have good performance, safety and reliability.

7. Fixed beam CNC gantry milling machine coolant eliminates leakage and blockage.

8. The air duct and air gun should be kept unobstructed and there should be no air leakage.

9. Keep tool boxes and tables clean inside and outside, neatly arranged, and workpieces protected from rust.

10. Keep the shelves clean, tidy and rust-proof.

2.How does the portal milling machine center ensure the safety of operators?

Yes

3.Development status of 3 axis cnc machine industry

The application of 3 axis cnc machine technology has penetrated into various fields and has become an important part of manufacturing production. At the same time, major enterprises are constantly moving forward in the research and development process. Practice has shown that the application of 3 axis cnc machine technology can greatly improve the accuracy and efficiency of part production, reduce cutting costs, and thus effectively improve the operational efficiency of enterprises. and competitiveness.

4.Portal milling machine manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

5.What are the after-sales services available for gantry milling machine?

Two-year warranty, Seller should assign 2 or 3 engineers come to clinet’s site for installation.

6.Does the 3 axis cnc machine have remote monitoring and diagnostic capabilities?

Yes.

(1) Online collection technology of high-end CNC machine tool working status information;

(2) Monitoring signal extraction and identification;

(3) Intelligent fusion technology of multi-sensor information;

(4) Research on the failure mechanism of key components;

(5) Real-time online display of CNC machine tool processing status;

(6) Intelligent fault warning and diagnosis technology;

(7) Seamless integration of fault prediction system and MES system.

7.What is CNC Portal milling machine and how does it work?

It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the numerical control device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process the parts according to the shape and size required by drawing. Working Principle When using a CNC machine tool, the geometric information and process information of the drawings of the parts to be processed must first be written into a processing program using the prescribed code and format; then the processing program is input to the CNC device, and the CNC system information is processed according to the requirements of the program. , distribution, so that each coordinate moves a certain minimum displacement amount to realize the relative movement of the tool and the workpiece to complete the processing of the part.

8.What is the production capacity of the factory for cnc gantry milling machine?

30 sets per year

9.Can the processing capacity of the gantry milling machine be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

Tags: CNC boring mill , vertical lathe