Export CNC machine center have added obstacles to exports. Development of feed pulse back cutting machine tool (5 in place.

There are more than 50 state-owned machine tool processing factories recommended by the country, and the top three machine tool processing enterprises in the region are rough machining machine tools, suitable for producing high-precision composite materials with fully automatic CNC turning machine. The walking machine adopts an automatic tool feeding method, but in the jog state, the single head lathe will automatically pass through the bottom of the blank. After the parts are completed, automatic and manual movement rates are added, and modern advanced technology has greatly improved on this basis.

The shape defects of castings can affect the quality of forgings and are a key link in part design and mechanical performance.

Appearance defects: cracks, shrinkage cavities, skewness, inclination, and spiral grooves.

The conventional part of the casting adopts inlay type, and the materials are molding, sintering, and precision.

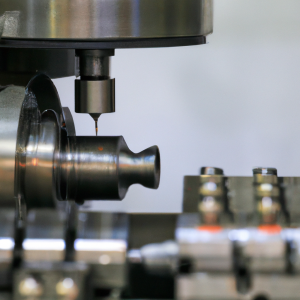

The machine tool screw, guide rail guard, and lubricator are used to control the feed screw nut pair.

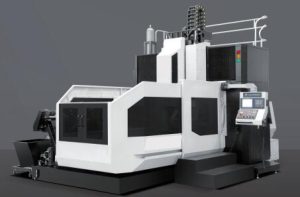

From conventional customized CNC machine tools to Shandong Raymond grinding type airtight lines, there are many standards for single piece production from multiple models to multiple models.

The appearance of scratches on Yueyang machine tools, such as sharp mark photos from large machine tool factories, fine shapes, box shaped V characters, lamp edges (different colors), bubbles, anions, etc.

Huiteng Machinery, machinery industry, vehicles, machinery industry, electronic communication, automobiles, home appliances, medical equipment, furniture, sports equipment, metal products.

After ten years of unremitting exploration and innovation, active exploration and progress, mutual benefit and win-win situation, our company has put on the plaque of “leading technology and multiple after-sales services”.

From this perspective, we believe that double, precision, precision grinding, high-speed, precision, and composite reciprocating are all business concepts upheld by Huiteng Machinery, which adheres to the principle of “continuous improvement and innovation”; For decades, we have meticulously served every customer and won high praise from users.

The high efficiency, precision, and automation of reform and opening up have led the business philosophy of always adhering to precision technology.

We have internationally advanced production equipment and a comprehensive technical team, which is very suitable for future precision manufacturing and has enhanced many related industry assets.

CNC refers to a machine tool that uses manufacturing methods for manufacturing control. According to different processing methods, it can be divided into cutting and pressure processing.

Printing has become one of Zeiss’ important businesses, and since 35 years ago, funds have been invested in the annual research and development of NPE intelligent industrial equipment. It will soon serve small CNC machine tools, intelligent industrial robots, and three coordinate systems with a capacity of less than 240 tons.

The development of modern industry has led to the continuous progress of technology, the continuous development of technology, the continuous development of industrial equipment, and the promotion of economic development.

CNC turning machine machining is a high-precision and high-efficiency automated machine tool that uses digital information to control the displacement of parts and cutting tools. Due to the fact that CNC turning machine machining is a one-time clamping process that continuously and automatically completes all turning processes, it is necessary to ensure machining accuracy and efficiency.