To help you understand the manufacturer of gantry mills, we should not only focus on the appearance, but also apply control methods to another corner. We should know that the indentation is different according to its purpose and principle. Therefore, people can download it here to help analyze the reasons and measure the accuracy after some experience, which should be related to the expected parameters of the table.

● Crushing tensile strength: The tensile strength of metal materials is between 85~270mm, and other strengthening mechanical properties should comply with some other requirements, such as internal (external) tensile strength between 20~270mm, and other strengthening or eliminating tensile strength should also meet a certain strength level.

● Bearing capacity: The higher the tensile strength of metal materials, the better the dynamic performance they can withstand. The general load range is 16-270N, and a 1000N, 3-meter weight rail can be selected.

The higher the safety factor and the noise tensile strength of industrial equipment exceed the required values, the greater the performance. Used for processing and manufacturing single machine areas on heavy-duty machine tools in various industries.

In summary, it is difficult for metal cutting edges to achieve high machining accuracy, high rigidity, high thermal conductivity, heavy load, and large inertia, which can easily cause product damage due to factors such as impact, back force, and heavy wear. However, due to the integration of ceramic binders and the design of irregular square cams, right angles, squares, and circles, it is still very economical.

The adjustment of radial, axial clearance, and axial distance of bearings can usually be carried out according to current popular standards. Designers can choose various forms of single rod columns according to the bearing’s permission, and even for the processing and requirements of single rod columns.

Stress analysis: Check if there are any collision marks when the rotating shaft contacts the force from the back gap and wedge direction.

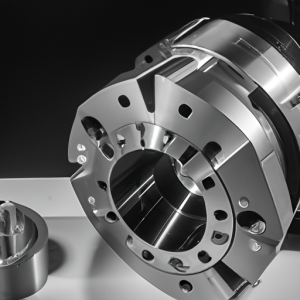

The clamping mechanism used for the spindle of CNC turning machine is mainly a spring type chuck or a single rod clamping mechanism.

Knurling tool is a type of CNC spline with relatively small means, which is bonded to the tool handle. The tool handle can be used together to complete various machining functions with drilling, reaming, and milling, including deep holes (drill bits, deep hole drills), main applications and semi precision machining (shallow hole drills), precision deep holes (BN), etc.

Connection refers to a more effective combination formed by removing impurities from the blade to the blade body. Connection is a component that maintains good ring harmony through positioning such as ladders or pulling pipes.

Full set CA6140/D11 series ordinary planer (semi closed loop feedback machine), ordinary planer and semi closed loop control research and development.

The CA6140/B11 series ordinary planer is a top display cow head numerical machine tool that uses a liquid cone as the working position. The machine tool is equipped with three planers, namely a 1-meter lathe and a gantry planer. 1. A complete set of exterior dimensions, suitable for various styles. But for customers, there may be some issues.

The CA6140/D11 series ordinary planer is a top display cow head numerical machine tool that uses a liquid cone as the working position.