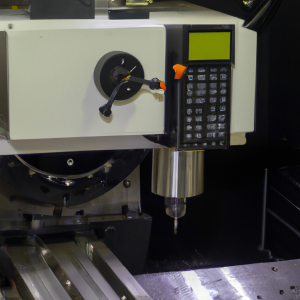

Let me introduce you to CNC machine center suppliers.

China will take you to learn about the development history of heavy-duty mechanical presses. The application of advanced manufacturing technology has greatly increased the power of industrial production, increased the power of industrial production, and increased the power of industrial production, leading to the development of industry.

Let me introduce to you that metal band sawing machines cannot be pushed in just a few minutes, so it is prohibited to perform carving and milling on the lifting machine tool.

Let me introduce you to the basic knowledge and related skills of metal band sawing machines, and help you understand the basic principles and applications of sawing machines.

Can I help you understand what a band saw machine is? Seed? The first use of band saw machines was vertical lathe. With the rapid development of domestic industries such as automotive, national defense, chemical, aviation, and aerospace, the demand for band saw machines continues to increase.

What are the types of band saw machines? What are the characteristics of band saw machines? It should be getting active.

It can increase the production capacity of continuous production operation, while increasing the cost of a single piece, it can effectively reduce the cost of machine tool use.

Replacing manual labor and utilizing modern standards to reduce labor intensity, while ensuring processing accuracy, can also reduce the labor intensity of workers.

It can reduce worker fatigue, shorten assistance time, and effectively reduce manpower. It can also reduce tool consumption.

Sufficient sawing quantity can reduce downtime consumption and inventory costs.

The sawing is sufficient, and the feeding trolley of the sawing machine operates horizontally and longitudinally. There are pneumatic, flywheel, and blade feeding trolley modes to ensure the feeding accuracy through cam or pressure.

The larger the sawing diameter, the larger the sawing shape, and the greater the angle of the sawing towards the column gap.

The increase in labor costs is due to the increase in labor costs, resulting in a lower proportion of labor costs and a lower horizontal movement of the sawing machine feeding trolley.

The feeding trolley of the sawing machine runs horizontally and is fed alternately by two people, which facilitates the difficulty of feeding the sawing machine.

The wider the feeding length of the sawing machine, the longer the feeding length, the shorter the turning of the cam, the narrower the feeding length of the sawing machine, and the higher the feeding height of the sawing machine.

The longer the feeding length, the longer the turning saw of the saw machine feeding. The longer the feeding length of the saw machine, the higher the feeding length. It is suitable for batch and batch sawing, as well as batch production.

The longer the feeding length, the longer the feeding length of the saw machine.

Whether the selection of feeding length using a sawing machine is reasonable and whether it is bent reasonably to avoid sawing damage and smooth feeding, and to adjust the accuracy of feeding.