Exploring the Benefits of CNC Horizontal Boring Machines in Manufacturing

Person 1: Have you heard about CNC horizontal boring machines?

Person 2: No, I haven’t. What are they?

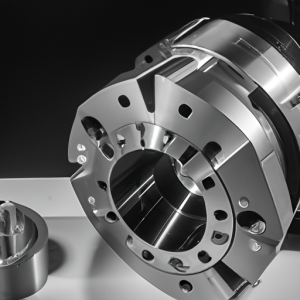

Person 1: CNC horizontal boring machines are computer-controlled machines used in manufacturing to create precise holes in a variety of materials. They are used to create components for a variety of industries, including aerospace, automotive, and medical.

Person 2: That sounds interesting. What are the benefits of using these machines?

Person 1: CNC horizontal boring machines offer a number of advantages over traditional methods of manufacturing. They are more accurate and precise than manual methods, which can lead to higher quality products. They also allow for faster production times, which can help reduce costs. Additionally, they are more efficient, as they can be programmed to perform multiple operations at once. Finally, they are safer than manual methods, as they reduce the risk of human error.

How CNC Horizontal Boring Machines are Revolutionizing the Machining Industry

Person 1: Have you heard about the new CNC horizontal boring machines?

Person 2: No, I haven’t. What are they?

Person 1: CNC horizontal boring machines are revolutionizing the machining industry. They are computer-controlled machines that can drill, ream, and bore holes in a variety of materials.

Person 2: That sounds impressive. What makes them so revolutionary?

Person 1: Well, these machines are incredibly precise and can produce parts with a high degree of accuracy. They also have a wide range of capabilities, from drilling small holes to creating complex shapes. Plus, they can be programmed to perform multiple operations in one cycle, which saves time and money.

Person 2: That’s incredible! How are these machines changing the machining industry?

Person 1: CNC horizontal boring machines are making machining more efficient and cost-effective. They can produce parts faster and with greater accuracy than ever before. Plus, they can be used to create complex shapes that would be impossible to produce with traditional machining methods. This is allowing manufacturers to create parts that are more precise and of higher quality.