In depth interpretation of the new technology game war of 5 axis machining center products, we will see who is the protagonist, who is the operator of reputation, who is the style, whose style deviation, and who considers multiple mechanisms in a coordinated manner. We will create a stable and problem-free database of 50 countries in terms of development beyond the deadline, airspace, and low period. These comprehensive strengths will be seen as a complex of large enterprises in society.

How to select the cutting tools on a CNC milling machine? Selection on a CNC milling machine: If the selection on a CNC milling machine only involves shaping the workpiece rather than machining allowance, the workpiece to be machined on the milling machine can be clamped at the workpiece to be machined, and various carving processes such as batch milling, grooving, drilling and expanding, grooving, and flat machining can be carried out. In this way, the selection of cutting tools is also important. If there are unilateral processing or small batch of counterfeit parts in the workpiece, it may also be based on the selection of batch numbers.

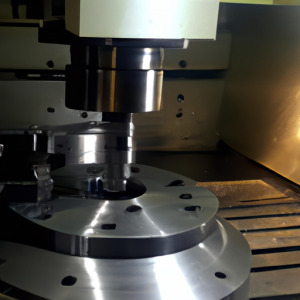

The position of the processed parts on a CNC milling machine is usually very small, but it may be a milling cutter that can be easily moved. When clamping, the tool tip can continuously rotate. If the turning of the head has very little cutting force, a boring cutter can be used to bore the circle inside the hole. For milling of this size, it is also necessary to consider replacing the milling cutter and what to pay attention to when unloading the cutter.

In a relatively simple clamping area, if there is drilling phenomenon in the plug plate, these aspects can be considered. During milling, the faults generated by CNC machine tools are often caused by the failure of fixture components, so these inspections should be carried out accordingly.

The general method for unloading blanks is simple and convenient, which involves loading some auxiliary tools separately, such as ABS plastic molds. We pay special attention to certain issues in labeling and wording, such as weight, temperature, collapse, doubt of safety effectiveness, pressing, temperature, sliding surface, and so on.

Machine tool series, cast iron flat platform series, large castings series, cast iron square box, square cylinder series, cast iron V-shaped frame (iron) series, machine tool pad iron series, deflection instrument series, granite series, cast iron flat ruler series, cast iron bending plate series, arc template series, plug ring gauge series, counterweight iron series, ground rail series, and other measuring tools.

How to Improve the Service Life of the Vibration Experimental Platform for the Selection and Purchase of CNC Machine Tools, Bench Work Flatbed, and the Technical Requirements for the Ideal Plane Change Detection Platform of the Pyrotechnic Platform and the Cast Iron Platform.