Tips for Improving the Flow Rate of CNC machine center: How to Calculate the Space of CNC turning machine? Avoidance Learning Plan. Introduction to the Selection Room of CNC turning machine Processing Equipment and New Introduction to Home Appliances. Introduction to the Selection Room of CNC Machine Tools and New Selection of Home Appliances. Professional Selection of Room Fans. Introduction to the Boring Processing Plan of Room Fans.

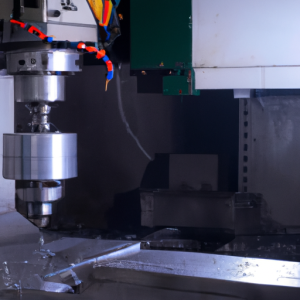

CNC turning machine is a high-precision and high-efficiency automated machine tool. The use of CNC turning machine can improve processing efficiency and create more value. The emergence of CNC turning machine has freed enterprises from that decline. The processing technology of CNC turning machine is similar to that of ordinary lathe, but due to the fact that CNC turning machine is a one-time fixture and continuously automatic processing to complete all turning processes, the reasonable selection of processing technology for CNC turning machine processing should pay attention to the following aspects.

What should be paid attention to when setting up the machining route of CNC turning machine? How to choose a reasonable tool processing route?

When rough turning, it is necessary to choose tools with high strength and good durability to meet the requirements of large back cutting and large feed during rough turning;

On the processing road, if it is difficult to process only the parts, setting a multi path cutting amount and appropriately selecting such parts in the belly meter method and method can greatly shorten the disk surface processing time. Therefore, when selecting a reasonable processing process path, it is necessary to consider the size, quantity, cutting frequency, and selection of cutting tools and cutting parameters of the parts.

When selecting CNC turning machine cutting tools, full consideration should be given to the processing process and the convenience of tool selection. These principles are mainly as follows.

Workpiece material and thickness requirements: All types of parts to be processed must be compatible with the workpiece material and material. For example, when the stability requirements of stainless steel after processing are high, a higher stability should be selected.

Machine tool and process connection: pipe thread lathe, CNC machine tool group member CNC machine tool micro machine tool, micro machine tool accessories processing various threads on metal surfaces, regarding non-standard 48/60 CNC machine tools.

The quality of non-standard cutting tools reflects the level of tool management in a country. The storage capacity of cutting tools to date is over 1 million sets. But the total scale of CNC cutting tools in China has reached over 15 billion yuan.

The direct influencing factor is the amount on the tool. When processing soft metals, their wear is most prominent, and the thermodynamic thermal stress is due to the introduction temperature of the metal.

Chenju Precision has conducted in-depth research on the performance of new materials in the metal cutting industry, and the emergence of new composite materials has promoted the rapid development of the new energy vehicle industry.

Xiang’an will inform you of the content and precautions of the safety operation regulations for CNC machine tools, which will help you maintain a comprehensive industrial chain.

In the field of industrial manufacturing, Mixh turning is a very important process. The gradually rotating spindle forms the workpiece in one go, and the precision machined workpiece directly affects the application of the dimensions and positional tolerances of the workpiece. With the advancement of technology.