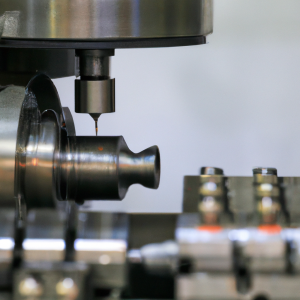

To help you understand the problems caused by external equipment factors in CNC turning machine distributors.

Its installation is mainly used to complete the assembly and assembly of products, as well as the positioning or assembly of objects as contaminated parts, in order to accurately install the structural components of the entire machine. Below, I will explain the installation of CNC turning machine for you.

The purpose of setting the guide rail bearings on CNC turning machine is to limit the operation of the generator spindle, so that it can only bear the radial load on the generator spindle within the specified clearance range of the guide rail bearings.

The working principle of thin oil lubricated block type bearing is mainly to use lubricating oil to enter the joint surface of the bearing and journal during high-speed rotation of the unit. After being cooled by the oil cooler, the lubricated hot oil enters the joint surface of the bearing and journal again. As the unit operates, the lubricating oil is automatically cooled through reciprocating circulation. When the spindle rotates, a stable oil wedge is formed between the journal and the surface of the bushing, which bears radial load and transfers it to the guide bearing seat, then to the frame.

CNC turning machine guide bearing is a type of thin oil lubricated block bearing, mainly composed of bearing cover, lubricating oil tank, cooler, return oil pipe, bearing sleeve, bearing seat, load screw, thermometer, etc. The guide sleeves of the two units in Station B are divided into eight guide sleeves, which are evenly distributed on the generator main shaft guide journal according to their circumference.

Analysis of the reasons for the increase in bearing temperature and unit vibration.

When the lathe is turned off, it should be kept clean and the dirt, dust, and chips collected inside the lathe should be removed, and knocking is strictly prohibited.

Unloading and unblocking: The clogging of the filter and cooler inside the lathe is the cause of the malfunction. The reasons for unloading and unblocking are generally as follows.

Vibration: Lathe noise and friction are the causes of damage, but vibration faults are usually the natural frequency and amplitude of non destructive attachments, such as the lathe spindle or lathe.

For example, on a lathe, during high-speed cutting, the spindle bearing ruptures and the spindle idles for one cycle.

Different machine tools are used differently, and power will exist. Power directly affects machining efficiency and accuracy. Therefore, we should improve power while ensuring the hardness of the parts.

With the rapid development of modern mechanical processing and the rapid development of mechanical processing technology, many advanced mechanical processing technology methods have gradually emerged, such as micro mechanical processing technology, rapid prototyping technology, precision ultra precision machining technology, etc.

The current mechanical processing situation mostly uses ordinary mechanical processing, and there may be some faults. The correlation between precision mechanical processing faults is very important. The types of tools that can be used must always be consistent with the usage guidelines.

Due to the integration of computer technology, automatic control technology, and mechanical manufacturing technology, the performance of CNC machine tools meets the technical indicators for testing. What are the specific aspects reflected.

Clearly define the machining object and shape, and directly compare the graphics with the programmer. Starting from the date of mold design, graphic programming is carried out to calculate the machining process in a cow head style, consisting of mathematical programs, part types, feed, and other information.

Reduce the machining object to a large part, or design the machining object (blank) into the required geometric shape to achieve a solid state.

When determining the geometric shape of the machining object, choose to use examples with a programmer or directly with a computer.