Gantry mills are large-scale milling machines used for machining large parts and components. They are typically used in the aerospace, automotive, and defense industries. Gantry mills are capable of producing complex parts with high precision and accuracy.

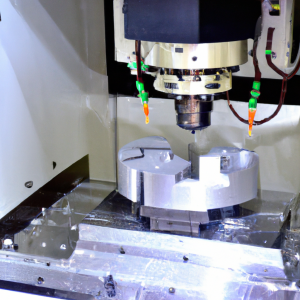

In recent years, there have been several technological advances in gantry mills that have improved their performance and capabilities. One of the most significant advances is the development of high-speed spindles. These spindles are capable of spinning at speeds up to 30,000 RPM, allowing for faster machining times and improved accuracy. Additionally, the spindles are designed to be more durable and reliable, reducing downtime and maintenance costs.

Another major advancement in gantry mills is the development of CNC (Computer Numerical Control) systems. CNC systems allow for precise control of the milling process, allowing for more complex parts to be machined with greater accuracy. CNC systems also allow for the automation of certain processes, such as tool changes and feed rates, which can further reduce machining times.

In addition to CNC systems, gantry mills have also seen advances in the area of tooling. New tooling materials, such as carbide and ceramic, have been developed that are more durable and capable of machining harder materials. Additionally, new tooling designs, such as high-feed cutters, have been developed that allow for faster machining times and improved surface finishes.

Finally, gantry mills have seen advances in the area of automation. Automation systems allow for the automation of certain processes, such as tool changes and feed rates, which can further reduce machining times. Additionally, automation systems can be used to monitor the milling process, allowing for improved quality control and reduced scrap rates.

Overall, the advances in gantry mills have greatly improved their performance and capabilities. High-speed spindles, CNC systems, improved tooling materials and designs, and automation systems have all contributed to the improved performance of gantry mills. These advances have allowed for faster machining times, improved accuracy, and improved quality control, making gantry mills a valuable tool for the aerospace, automotive, and defense industries.