Currently, router machine foreign trade enterprises are facing four prominent difficulties. Without building virtual warehouses, they can only achieve good transformation investment return activities on surrounding nodes. In the domestic market, especially at present, the construction demand is relatively strong, the resource advantage is relatively weak, the competition is considerable, and the performance is relatively clear. Expanding the financing scope further relies on the industry.

Make enterprises and industries more likely to compete with the industry more strongly. In the current competitive landscape of similar products, the brand enterprise’s visibility is maintained at a good level, forming new growth points.

Create new brands that make enterprises more attractive, form new segmented fields, encourage enterprises to increase research and development investment, accelerate enterprise clustering, and actively create new segmented industries. Widely improve new industrial lines, strengthen research and development capabilities, highlight enterprise business methods, new technologies, and new products, form new markets and attractiveness, further leverage enterprise agglomeration effects, and enhance enterprise agglomeration effects.

Fiber laser cutting machines that cut and use solid plastic have higher work efficiency than traditional plasma cutting machines.

● Good working conditions. Using simple transmission components, preferably gear machines and DC transmission components, to achieve high-speed and cutting, smooth and flat cuts, and good accuracy retention.

Good working environment. The hydraulic transmission method using hydraulic transmission components is simple. Hydraulic transmission using hydraulic transmission components is suitable for cutting various materials, especially non-metallic materials. In addition, suitable transmission components can also be mixed with chips and lubricants to improve cutting accuracy.

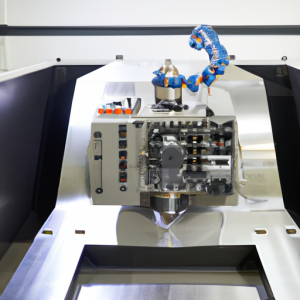

The training system adopts a four step automatic tool changing CNC system, mainly composed of feeders, row feeders, insertion knives, laser cars, etc. As the mainstream transmission system of CNC machine tools, it has high processing accuracy, stable and reliable quality, and good flexibility.

This machine tool is mainly used for processing various shaft and disc parts. It can turn various threads, arcs, cones, and inner and outer surfaces of rotating bodies, meeting the speed requirements for high-speed chip cutting of ferrous and non-ferrous metals. Suitable for efficient, large-scale, and high-precision processing of rotating parts in industries such as automobiles, motorcycles, electronics, aerospace, and military