Exploring the Benefits of Vertical CNC Lathe Programming for Machinists

Are you a machinist looking to increase your efficiency and productivity? If so, you may want to consider vertical CNC lathe programming. This type of programming can help you save time and money while producing high-quality parts.

Vertical CNC lathe programming is a type of computer numerical control (CNC) programming that is used to control the operation of a lathe. It is a type of programming that is used to control the movement of the cutting tool and the speed of the spindle. This type of programming is used to create parts with a high degree of accuracy and repeatability.

The benefits of vertical CNC lathe programming are numerous. First, it can help you save time and money. By using this type of programming, you can reduce the amount of time it takes to produce a part. This can help you increase your productivity and reduce your costs.

Second, vertical CNC lathe programming can help you produce parts with a high degree of accuracy and repeatability. This type of programming allows you to program the exact movements of the cutting tool and the speed of the spindle. This can help you produce parts with a high degree of accuracy and repeatability.

Third, vertical CNC lathe programming can help you reduce the amount of scrap material produced. By using this type of programming, you can reduce the amount of scrap material produced by ensuring that the cutting tool is programmed to cut the exact size and shape of the part. This can help you reduce the amount of scrap material produced and save you money.

Finally, vertical CNC lathe programming can help you increase your safety. By using this type of programming, you can reduce the risk of injury by ensuring that the cutting tool is programmed to move in a safe manner. This can help you reduce the risk of injury and increase your safety.

Overall, vertical CNC lathe programming can help you save time and money while producing high-quality parts with a high degree of accuracy and repeatability. If you are a machinist looking to increase your efficiency and productivity, you may want to consider using this type of programming.

Understanding the Basics of Vertical CNC Lathe Programming: A Comprehensive Guide

Welcome to the world of vertical CNC lathe programming! This comprehensive guide will provide you with the basics of vertical CNC lathe programming so you can get started on your journey to becoming a CNC lathe programmer.

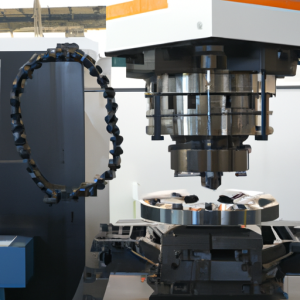

First, let’s start with the basics. A vertical CNC lathe is a computer-controlled machine that is used to shape metal and other materials into a variety of shapes and sizes. It is a type of CNC (Computer Numerical Control) machine that is programmed to move the cutting tool in a specific pattern to create the desired shape.

Now that you know what a vertical CNC lathe is, let’s talk about how it is programmed. Programming a vertical CNC lathe involves writing a program that tells the machine what to do. This program is written in a language called G-code. G-code is a language that is used to control the movement of the cutting tool and other components of the machine.

When programming a vertical CNC lathe, you will need to consider the size and shape of the material you are working with, the type of cutting tool you are using, and the speed and feed rate of the cutting tool. You will also need to consider the type of finish you want to achieve on the material.

Once you have written the program, you will need to load it into the machine. This is done by connecting the machine to a computer and then transferring the program to the machine. Once the program is loaded, the machine will begin to execute the program and create the desired shape.

Now that you know the basics of vertical CNC lathe programming, you are ready to start your journey to becoming a CNC lathe programmer. With practice and dedication, you can become an expert in this field and create amazing shapes and sizes with your vertical CNC lathe. Good luck!