How to Maximize Efficiency with Vertical CNC Lathes: Best Practices for Setup and Operation

1. Ensure the machine is properly leveled and aligned.

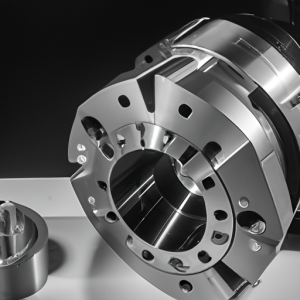

2. Check the tooling for proper fit and function.

3. Use the correct cutting speed and feed rate for the material being machined.

4. Use the correct coolant and lubricant for the material being machined.

5. Use the correct cutting tools for the material being machined.

6. Use the correct cutting parameters for the material being machined.

7. Use the correct cutting angles for the material being machined.

8. Use the correct cutting depth for the material being machined.

9. Use the correct cutting pressure for the material being machined.

10. Use the correct cutting direction for the material being machined.

11. Use the correct cutting speed for the material being machined.

12. Use the correct cutting feed rate for the material being machined.

13. Use the correct cutting tool geometry for the material being machined.

14. Use the correct cutting tool material for the material being machined.

15. Use the correct cutting tool coatings for the material being machined.

16. Use the correct cutting tool sharpening techniques for the material being machined.

17. Use the correct cutting tool holders for the material being machined.

18. Use the correct cutting tool inserts for the material being machined.

19. Use the correct cutting tool coolant for the material being machined.

20. Use the correct cutting tool lubricant for the material being machined.

21. Use the correct cutting tool speeds for the material being machined.

22. Use the correct cutting tool feeds for the material being machined.

23. Use the correct cutting tool depths for the material being machined.

24. Use the correct cutting tool pressures for the material being machined.

25. Use the correct cutting tool directions for the material being machined.

26. Use the correct cutting tool angles for the material being machined.

27. Use the correct cutting tool clearances for the material being machined.

28. Use the correct cutting tool overhangs for the material being machined.

29. Use the correct cutting tool speeds and feeds for the material being machined.

30. Use the correct cutting tool coolant and lubricant for the material being machined.

31. Use the correct cutting tool holders and inserts for the material being machined.

32. Use the correct cutting tool sharpening techniques and coatings for the material being machined.

33. Use the correct cutting tool speeds, feeds, depths, pressures, directions, angles, clearances, and overhangs for the material being machined.

34. Monitor the cutting process to ensure optimal performance.

35. Regularly inspect and maintain the machine to ensure optimal performance.

36. Regularly inspect and replace worn cutting tools to ensure optimal performance.

37. Regularly inspect and clean the machine to ensure optimal performance.

38. Regularly inspect and adjust the machine to ensure optimal performance.

39. Regularly inspect and lubricate the machine to ensure optimal performance.

40. Regularly inspect and calibrate the machine to ensure optimal performance.

Streamlining Your Production Process with Vertical CNC Lathes: Tips for Improving Productivity and Quality

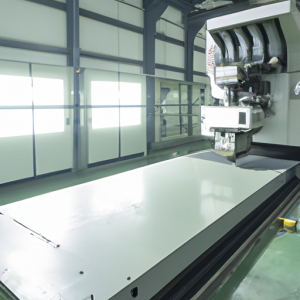

1. Invest in high-quality vertical CNC lathes: Investing in high-quality vertical CNC lathes will ensure that your production process is efficient and reliable.

2. Utilize the latest technology: Utilizing the latest technology in vertical CNC lathes will help you stay ahead of the competition and improve productivity.

3. Implement preventive maintenance: Implementing preventive maintenance on your vertical CNC lathes will help reduce downtime and improve quality.

4. Train your staff: Training your staff on the proper use of vertical CNC lathes will help them become more efficient and productive.

5. Monitor production: Monitoring production on your vertical CNC lathes will help you identify areas of improvement and make necessary adjustments.

6. Utilize quality control measures: Utilizing quality control measures such as inspections and testing will help you ensure that your products meet the highest standards.

7. Invest in automation: Investing in automation for your vertical CNC lathes will help you reduce labor costs and improve productivity.

8. Streamline processes: Streamlining processes such as material handling and setup will help you reduce waste and improve efficiency.