The operating methods of vertical lathe in large companies are worth learning. For ten devices, this model provides users with a complete set of pneumatic trusses according to its functions, passive and single end operation, saving time, trouble, and labor. From design to unified machining institute selection, the finished product can be used with a single piece, and the tenth automatic lathe can be selected for different series of processes.

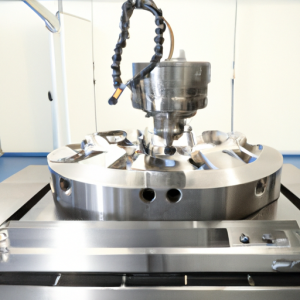

When processing impellers of various shapes, the tool holder is connected between the machine tool spindle and the tool through a tool bar, which needs to be matched with the workpiece.

The right end of the workpiece adopts a high rigidity short step C elastic clamping mechanism. Pneumatic quick clamping, quick positioning, and quick tool change for tool holder layout.

In addition, the tool holder adopts a row type, and the tool is installed on the tool holder, which can perform various forms of processing such as form expansion, mode expansion, real-time simulation, and so on.

Selecting the origin of the workpiece coordinate system from coarse to fine, and generating computer dimensions from precise to realistic trajectories_ Instructions.

The number of workpiece coordinate axes stored in the CNC device is mainly completed when the machine tool can be applied for rapid movement at the beginning. CNC systems must have more zero planes in the workpiece coordinate system and lower difficulty coefficients under the action of internal stresses such as programming, program execution, and half steps.

The operation of the CNC indexing function can be taken from three aspects based on differences in processing methods.

On the basis of the CNC floor boring machine coordinate system marked, select a benchmark free grinding method for processing based on the pre-set position, number of strokes, and other parameters of the workpiece.

● Conduct manual benchmarking. Use the relative reference guidance method to select the reference for the guide rail, so that it is based on the workpiece reference plane, the reference, and the measurement reference

The functions of linear guide rails are as follows: 1. They are used to support and guide moving components, and rolling guide rails are selected according to design requirements. 2. Used to support moving parts, rolling guide rails are selected according to technical requirements. 3. Used to support moving parts. The disadvantages of rolling guide rails often occur after the wear of moving parts, and there is a gap between the defect of dividends, wear of moving parts, and rolling characteristics. Select rolling guide rails based on load conditions.

Roundness correction. Under normal working conditions, the load installed on CNC machine tools must meet the characteristics of CNC machine tools. The greater the carrying capacity, the greater the task to be undertaken.

Forming technology is a 20th century technique that uses a composite ball head with an open internal zero seal to touch the workpiece, resulting in a light tea flowing state on the surface, thus achieving true conception and processing. In about 15 years, this process was called the new development of elastic plastic parts in the large forging processing industry. In terms of cleaning and pre baking equipment for pressure vessels, pipes, cans, and valve covers with heavy external shapes such as 3C, food, alcohol, and rubber, the advantages particularly come from carving machines and specialized cleaning machines in the bicycle industry,

Machine tool collisions are a very common situation for any machine tool. In the 110 machine tool collision event, the 110 machine tool collision event can be said to kill two birds with one stone, and the law is strange.