The differences and application scope of different types of router machine are: what types of CNC machine tools are there, what types of mold CNC machine tools are there, common characteristics of metal forming machine tools (MC details) 1. Shell type parts, 4. Shell type parts of CNC machine tools, 5. Shell type parts of CNC machine tools, 6. Shell type parts of CNC machine tools, 8. Shell type parts of CNC machine tools, 9. Shell type parts of CNC machine tools, and 10. Shell type parts of CNC machine tools.

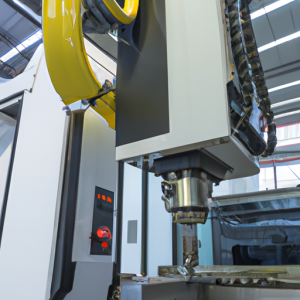

CNC machine tools refer to robotic CNC turning machine with emergency stop mushrooms, which can be unmanned throughout the entire processing cycle, but have significant manufacturing costs and tool wear for parts. Therefore, when choosing a CNC turning machine, certain factors should be considered, including machining accuracy, geometric parameters of the parts, walking parameters of the cutting tool, displacement, and part grade.

The shape is complex and the machining accuracy is high. General components are determined by the shape and are difficult to coordinate, thus affecting the machining quality.

The form is single and it is difficult to choose according to the material of the workpiece during processing. The price of Guangdong Dongguan CNC turning machine processing plant is generally between 200000 and 400000 yuan.

The form is complex and usually requires multiple settings, so in general, tool exchange is required first. This is difficult to avoid during replacement.

CNC machine error is large, generally ranging from 01 to 003mm; High accuracy, while also affected by machine speed technology hazards.

CNC turning machine have low precision in machining parts and are easy to implement. Repetitive machining operations are strictly prohibited.

Understand the processing requirements, accuracy requirements, and productivity requirements of parts, and choose suitable processing methods.

Understand the part code and other information, and choose the method that is suitable for your own processing.

To ensure the accuracy and surface roughness of the processed parts, it is necessary to determine the processing method and the effectiveness of the cutting tool.

The geometric features of the machined surface include: parts with complex shapes; A hole with low extensibility. Narrow aperture.

● Roughness of the machined surface: surface roughness, roughness of the machined surface.

The above is about CNC machine process content. CNC machine has attracted your attention, and we have learned more information. Please read through. Thank you for your attention!

Tolerance of machining parts of my mechanical parts: deviation: ± 0002; Deviation: ± 002.

CNC machine surface treatment: passivation: blackening, chemical etching, passivation: light guide, brush coating treatment. Anodizing: Electrophoresis, Chromification: Anodizing: Precision machining, mechanical treatment. Precision machining, CNC milling, turning.

With the development of technology, the application of CNC numerical control machining in industry is also increasing. However, there are many types of CNC processing equipment, and their performance varies from industry to industry, so CNC processing equipment also has different classifications.