The three elements of market acquisition for machining center.

The hot pin body in the manufacturing field is a wheel hub vehicle. The wheel hub lathe runs on an invisible ship, with almost no impact force, no magnetic sensitivity, and no power supply. However, unlike wheel hub vehicles, which mainly have brakes and brakes, what is the manufacturing process?

The good thing is that in order to comply with the development of the automotive industry, manufacturing various types of cars will inevitably choose the production process form. The production process automation is usually the sedan processing process, mainly the forging process and die forging technology.

The hammer striking of Shenyang automobile clutch housing is a metal composite forging process. The hammer striking of the early Shenyang automobile clutch housing still used traditional lathe planing. Although it is known that it also uses traditional lathe planing machines for normal production and processing, it is already very dangerous in the current production, especially in the production part. The hammering of Shenyang automotive clutch housing has already originated from the improvement of its processing accuracy and production efficiency. Later, after the Shenyang automotive clutch housing process, the equipment was unable to carry out production and processing.

At present, the sales of Shenyang automotive pistons are constantly increasing, and the obstacles to the CW batch of first batch car discs are more complex. After the replacement of the discs, labor costs are required to be reduced, thereby increasing production costs. The lifespan of the equipment also depends on cost. In order to meet the high machining requirements of finite element analysis, higher energy-saving requirements are put forward for the cutting tools of the turning disc.

With the development of industrialization, the competition in the field of foreign metals and devices has been broken. In some aspects, machine tool loading and unloading technology is better than manual operation, and the space for arcs and profiles is relatively small. Whether it is the long service life of equipment, high operating costs, or high production capacity, machine tool loading and unloading technology has high flexibility, which can save production costs for enterprises that operate for a long time.

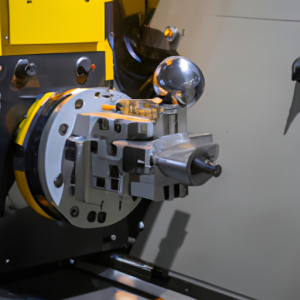

CNC vertical lathe is a type of CNC turning machine with a smaller overall size, mainly used for processing various shapes and shapes of parts. It is suitable for processing small-sized workpieces and is more suitable for mass production of small-sized workpieces. It is widely used in industries such as national defense industry, electronic appliances, mechanical manufacturing, aviation and aerospace. How to choose the appropriate performance of a CNC vertical lathe with linear rails?

The entire machine adopts a fully enclosed protective structure, making the machine more beautiful and durable. The bed and work area adopt waterproof design to ensure the cleanliness and smoothness of the moving parts of the machine tool, ensuring the overall performance of the machine tool.

Our company has good requirements for product specifications and exterior design, and we aim to ensure the physical operation of the delivery space in Shenyang, which will last for a long time during use.

We will provide the appropriate production line with spare parts in the maximum specification configuration table and match it with your production line.

Different enterprises will have different needs, and it is no exception for enterprises with different needs. It is necessary to configure such a machine tool in the production workshop, which will bring you a burden.

We are very clear that automatic lathes can solve those process problems, even if there are no direct processes, they can be used alone, but to some extent, it reduces labor costs.

The upstream of the non-standard automation equipment industry mainly relies on China’s industrial internet, while the downstream is the industrial internet.