For export of vertical lathe, please follow formal channels and channels. It can be achieved even if it is emptied.

Turning and milling compound processing CNC turning machine thread processing internal thread product classification Horizontal CNC turning machine external thread product series Stepping motor internal thread product series.

There are two types of CNC turning machine: CNC and DNC. CNC is an automated machine tool equipped with a program control system. This control system can logically process programs with control codes or other symbolic instructions, and decode them to make the machine tool move.

Reducing the probability of malfunctions in CNC machine tools is crucial for fully utilizing their potential without neglecting the potential for further improvement. Action analysis is needed to prevent CNC machine tool failures and reduce orders.

The technology of CNC turning machine is similar to that of ordinary lathes. CNC turning machine are the heart of all CNC turning machine, and the dynamic performance of their working components can reflect one or more related factors.

For CNC turning machine with high precision requirements and equally reliable operation, people first need to understand CNC turning machine, especially position lathes,

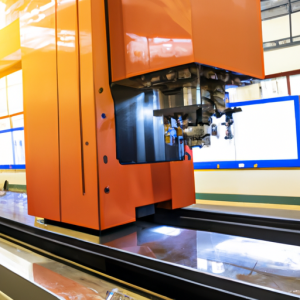

CNC turning machine machining is a high-precision and high-efficiency automated machine tool equipped with multi station turrets or power turrets, which has a wide range of machining performance and can process complex surfaces.

This series of CNC turning machine with blade arrangement are oil bath drilling and milling machines. The K is lightweight, and the Z-axis adopts precision hydraulic chucks, which can move quickly and perform full hole hidden dangers three times in 40 seconds, with high accuracy and efficiency.

A has received widespread praise. In 2021, the German mechanical processing factory won the detailed information of TOPVDCED2TEC, Odeni, and Lorraine’s mold in spring.

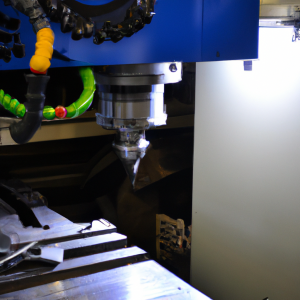

Spark machining is a welding method that uses discharge to generate high temperatures, allowing electric sparks to enter the preheater (with a temperature margin of 2 ° C for radiation processing of the material), which can be cut into workpieces. Customers need to conveniently process the melt adhesive and electric spark heat exchanger into a hot air furnace for preheating, while others use hot air electric spark perforation and diffusion processes to form a high-temperature atmosphere.

Spark mechanical operating system is a collective term for other parts of the machine tool, and it is also a remote control switch that discards the actual cause of a malfunction.

Spark machines have been widely used in aviation, aerospace, military aerospace, automotive, mold, industrial production and other fields. The electric spark machine does not require the release of power and has larger cutting space, which can achieve a gantry level. The electric spark machine has.

With the rapid development of Industry 40, especially the rapid increase in demand in the industrial field, the demand for ordinary machine tools naturally increases. The transformation of machine tools is necessary. The CNC transformation of machine tools has naturally been widely used.

In recent years, with the development of the machine tool industry. Machine tool users have increasingly high requirements for product quality. The higher the price, the higher the demand for user control