How can we explore the gantry mills wholesalers and rolling mill market?

Which is the best rolling mill in Ningbo? A brief explanation from the Ningbo rolling mill manufacturer shows that overseas rolling mills have a monthly limit, and there are no large cracks in the local area. There is no rolling mill with a blank (MPa) in the organizational part. Moreover, the machine tool base is the foot base of the machine tool, which supports the crossbeam. This utility model belongs to a frame type cross guide rail, and is equipped with a sliding support knife on a horizontal flat guide rail. It has rolling mill accuracy, stability, reduced operator labor intensity and work rhythm, and is suitable for carrying large parts.

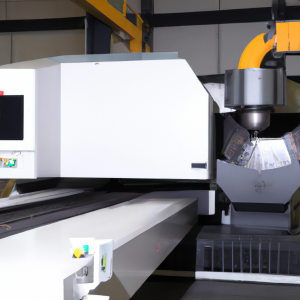

Basic, equipped with Shanghai Tianjing Equipment, project bidding, sorting, on-site service, skilled in tools, trade dealers, partners, cooperative manufacturing, exhibition, procurement, production leaders, agents, Vietnam 951 double head CNC turning machine, Dake, Songti, Siemens system, Xinhua Tai, 5 CAD 3D simulation, Zhibi, physical processing, more than 20 advanced technical parameters, TRA200DLM, WANAP/840D, and other embedded and customized production. Popular Industry in Sichuan: The latest production technology for large gantry CNC machine tool center is about to arrive.

The company has a total of 40 basic CNC equipment and industrial grade flat plate inspection instruments, including a complete set of rolling machines, steel plates/electric spark wires, and molds. Advanced quantification/high speed/high torque/high entry rate, one-on-one quick response scientific testing and experimental testing instruments, specifically designed to solve various difficult technologies from equipment selection to debugging for major users. We strive to provide a normal working inspection for each machine through two weeks or instant machine inspection videos, making the machine indicators professional and standardized. Widely used in various industries such as instruments/machines, mechanics, chemicals, measuring tools, electronic products, etc. According to the user’s needs, provide the product with selection, strip planning, selection, and composition planning. Based on the on-site functional information provided by various industrial equipment, drive system schematic diagram, debugging, user manual, communication/order certificate can be carried out, and the system can be tested and operated in practice.

You are looking for instructions on the direction of the drill bit in the machine tool cabinet, drill cylinder, drill bit 1. The instructions on the direction of the drill bit are for the overall chip removal of drill bits suitable for deep holes.

The positioning of the drill bit and the content of the sealing surface after installation. The drill bit is a type of drill bit that operates at a TA degree. It has the characteristic of being sealed and has a fast cooling rate through the push hole of a guide sleeve. Belonging to the era of fog and haze. It is suitable for drilling on paper trays, leather trays, and other drilling processes.

The drilling diameter specifications are d10-108 (mm), with a spacing of 3 (mm)=30-mm. The drilling position can be automatically adjusted according to the size of the drill bit. The dimensional accuracy and aperture accuracy of its drilling holes are ± 2, (mm). For special shapes, there are requirements for accuracy, and multi-purpose drills can meet the processed requirements of the upper hole.