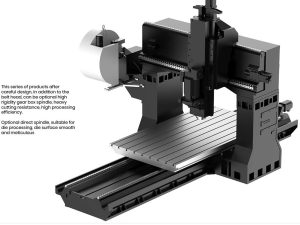

Gantry mills are a type of milling machine that uses a gantry frame to support the cutting tool. The gantry frame is a large, rigid structure that is mounted on a set of tracks or rails. It is typically used for large-scale machining operations, such as milling, drilling, and boring. Gantry mills are often used in the aerospace, automotive, and shipbuilding industries.

Gantry mills are highly versatile and can be used for a variety of machining operations. They are capable of performing complex operations such as contouring, drilling, and tapping. Gantry mills are also capable of performing multiple operations simultaneously, which makes them ideal for high-volume production.

Gantry mills are typically equipped with Computer Numerical Control (CNC) technology. CNC technology is a computer-controlled system that allows for precise control of the cutting tool. CNC technology is used to program the cutting tool to move in a specific pattern and to cut a specific shape. CNC technology is used to control the speed, direction, and depth of the cutting tool.

CNC technology is used to program the gantry mill to perform a variety of machining operations. CNC technology is used to program the cutting tool to move in a specific pattern and to cut a specific shape. CNC technology is also used to control the speed, direction, and depth of the cutting tool.

Gantry mills are highly efficient and precise machines that are capable of performing a variety of machining operations. They are used in a variety of industries, including aerospace, automotive, and shipbuilding. Gantry mills are equipped with CNC technology, which allows for precise control of the cutting tool. CNC technology is used to program the cutting tool to move in a specific pattern and to cut a specific shape. CNC technology is also used to control the speed, direction, and depth of the cutting tool. Gantry mills are highly versatile and can be used for a variety of machining operations.