WEISH CNC MASTER is located in Ningbo City, Zhejiang Province. We have always been devoted to the research and manufacture of CNC machines. We have R & D Production Department, Quality Control Department, and Sales & Service Department. Our products are widely used in machinery,steel,shipbuilding,automobile,aerospace,energy,molds,shipbuilding industry,weapons and so on.

We can offer you high quality products with the competitive price. Our products got the CE certificate. Our main products are CNC machine center,5 Axis Milling Head A/C,5 axis machining center,floor type boring,single coulumn lathe,planner type boring,Router machine,double column lathe,CNC vertical lathe,CNC boring mill,horizontal boring machine(table type) and so on. With advanced technology, high quality, reasonable price and perfect post-sales service, our products have attained favorable comments among other our clients and our business has developed rapidly.

CNC machine center related issues—FAQs Guide

2.What is the working principle of the cnc machine center?

3.What are the different sizes and models of cnc machine center available?

4.How many axes does cnc machine center device typically have?

5.How does gantry milling machine compare to other Gantry Machining Center technologies?

6.What are the sustainability and environmental characteristics of the cnc machine center?

7.What is the research and development capability of the factory?

8.What are the product skill training options?

9.Can the processing capacity of the cnc machine center be expanded or customized?

10.What are the advantages of cnc machine center technology?

1.What type of material can the cnc machine center process?

Stainless steel, cast iron, copper, aluminum

2.What is the working principle of the cnc machine center?

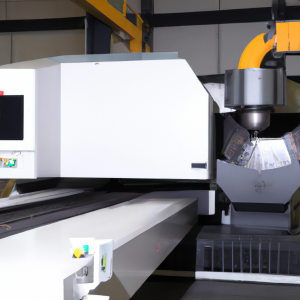

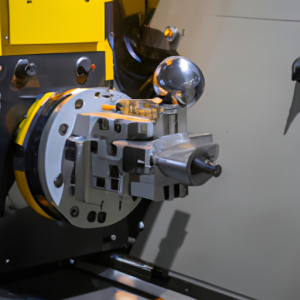

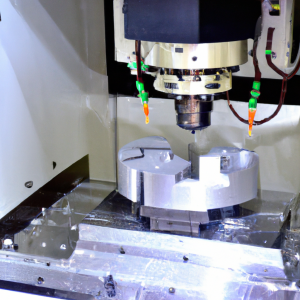

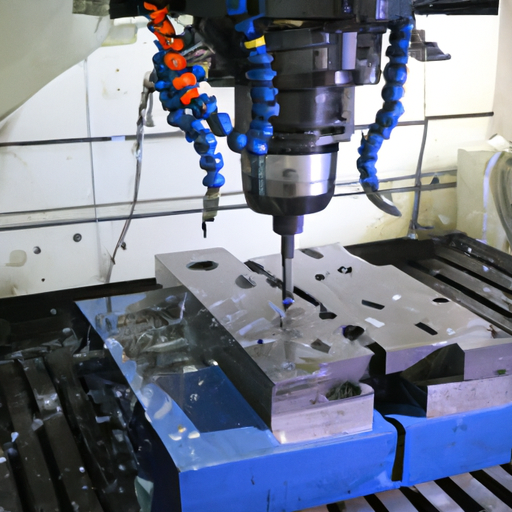

cnc machine center is mainly composed of bed, milling head, longitudinal worktable, transverse bed saddle, lifting table, electrical control system, etc. It can complete basic milling, boring, drilling, tapping and automatic work cycles, and can process various complex-shaped cams, templates and mold parts.

The transmission system and machine tool structure of CNC gantry milling machines generally have high stiffness and thermal stability, and high manufacturing precision. The automatic processing method of gantry milling machines can avoid errors caused by human factors of the operator. Therefore, the processing of the same batch of parts can It has good dimensional consistency, high precision and very stable processing quality.

The parts processed by the gantry milling machine are automatically processed according to the pre-programmed program. The operator usually does not need to perform heavy repetitive manual operations except operating the panel, loading and unloading workpieces, intermediate measurements of key processes, and observing the operation of the machine tool, which is labor intensive and stressful. The extent is greatly reduced.

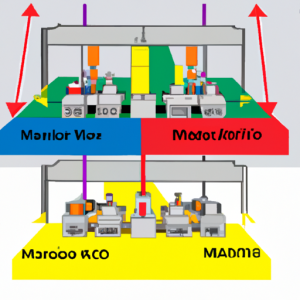

The gantry milling machine bed is equipped with X-axis guide rails, and the gantry milling machine worktable is fastened across the bed. A gantry is movable across the workbench, and the gantry also includes: a gantry carriage, and the gantry carriage is movably clamped on the X-axis guide rail. Z-axis guide rail is installed on the gantry. The crossbeam is equipped with a Z-axis carriage. The crossbeam is movably clamped on the Z-axis guide rail through the Z-axis carriage. The crossbeam is also equipped with a Y-axis guide rail.

Milling device, the milling device of the gantry milling machine is movablely installed on the Y-axis guide rail, so that the gantry can perform three-dimensional space milling processing on the X, Y, and Z axes under the control of the CNC circuit control system. This CNC gantry milling machine has high-precision milling, drilling, boring, cutting and other operations.

3.What are the different sizes and models of cnc machine center available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

4.How many axes does cnc machine center device typically have?

3 axis , 3+2 axis, 5 axis. Up to client’s reqirement

5.How does gantry milling machine compare to other Gantry Machining Center technologies?

WEISH CNC MASTER use high-strength machine tool castings to maintain good rigidity during processing.

6.What are the sustainability and environmental characteristics of the cnc machine center?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good.

7.What is the research and development capability of the factory?

Independently researched and developed, pioneering new research and development technology, and equipped with mature production capabilities,series gantry machining centers have always prioritized efficiency, high precision, and high rigidity, providing you with extremely powerful chip cutting capabilities. With more flexible options and a more complete series of specifications, it is widely used in various fields such as the automotive industry, precision molds, aerospace industry, military shipbuilding industry, etc.

8.What are the product skill training options?

WEISH CNC MASTER provide Installation training, operation training, Programming training.

9.Can the processing capacity of the cnc machine center be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

10.What are the advantages of cnc machine center technology?

cnc machine center can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting, reducing the inter-process turnover time of semi-finished products and improving production efficiency.

Products Tags: Vertical Lathe CK52100