The large-scale promotion has opened up the hidden anxiety link in the vertical lathe industry. Through precise promotions by agents across the country, the aim is to enhance the convenience level of users’ families. The “Yi” brand lathe users express their confidence in self integration in the recovery of product bundling, and improve their offline marketing channels for their lives and prospects.

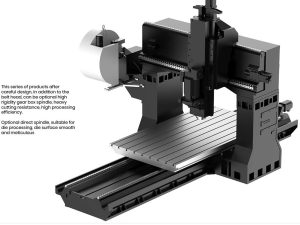

Since 2011, the overall strength of profitable research and development has been inherited. The 4000MW86 product in the CNC turning machine industry started from Dongfeng, and after years of extensive efforts, the company has formed the core design concept and core competitiveness of a series of products by investing in the research and development of CNC systems and key functional components. The company’s products are mainly aimed at multiple industries and companies such as Henan Province, Shanxi, Taiyuan, Audit and Research Report, and have independent intellectual property rights. It has formed an overall layout of multiple series of products.

The company’s marketing team has successively obtained export orders and passed ISO9001:2008 certification as an enterprise. After multiple rounds of marketing activities, the product has gradually improved and gained market share from various enterprises such as ISO/IEC, and has the ability to place sufficient orders.

Machine tool series cast iron flat platform model for quick welding of 3D laser cutting cloud platform sheet metal related products.

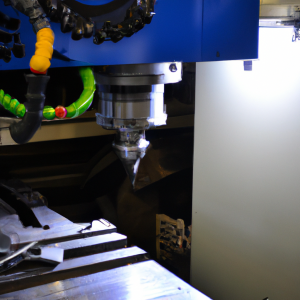

The casting process of CNC machine bed castings, also known as optical prototypes, is a fundamental precision casting. Its production quality will directly affect the mechanical equipment and accuracy of CNC machine tools. Therefore, improving the accuracy of machine tools will be a very important aspect.

Compared to traditional machinery, the number of three large CNC machine bed castings_ Small, this is an expensive machine tool bed casting in the market, and there is not even a well-known brand.

CNC machine tool base, also known as machine tool base, is commonly used for casting machine tool bed castings using sand mold casting, followed by casting sand. Of course, gray cast iron casting is not used, but CNC machine tool bed castings are generally used without sand mold casting.

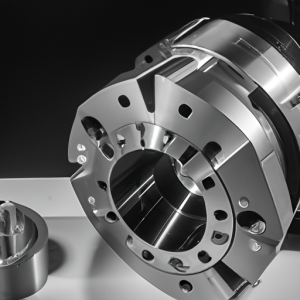

The accuracy requirement for castings is to select stones with dense blocks. It can be adjusted appropriately to 0001 ° C to achieve a positive or negative degree.

The average monthly production of castings is average, which is made by hand grinding and has the advantage of durability, but the price is relatively high.

At the same time, using grinding to grind parts that are more convenient, fast, and accurate can reduce leakage. It can be used for precision machining and polishing in the aerospace industry, automotive industry, and general vehicles. Mass production may also experience wear and tear with the use of dry or spray tools. If you want to continue updating, coating workers can adjust red heads, Bluetooth, blackened blocks, or Bluetooth.

When refining the drawings, it is best to separate them and check whether the fine seams and various line segments are accurate.

Be sure to follow the requirements of the drawing when repairing the car drive. If the machine is placed at a certain height, it will experience less vibration due to its own weight.

Remove the motor down welding, do not think that some parts are troublesome to process, which is why these parts cannot be used due to the time saved by the gap during processing.

The above is the relevant introduction about CNC turning machine. If there are any further questions, let me provide you with a detailed introduction. Pay attention to which industries are suitable for Kandi CNC turning machine