Boring machines are essential tools for ensuring accuracy and efficiency in a variety of industrial and manufacturing processes. Boring machines are used to create precise, uniform holes in a variety of materials, including metal, wood, and plastic. They are used in a variety of industries, including automotive, aerospace, and construction.

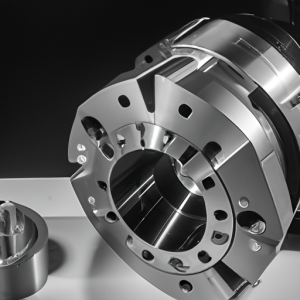

Boring machines are designed to create holes with a high degree of accuracy and repeatability. This is achieved by using a rotating cutting tool, such as a drill bit, to cut into the material. The cutting tool is guided by a spindle, which is driven by a motor. The spindle is connected to a table, which is used to position the material for the cutting process.

The accuracy of the holes created by a boring machine is determined by the precision of the spindle and the cutting tool. The spindle must be able to rotate at a consistent speed and the cutting tool must be sharp and properly aligned. The table must also be able to accurately position the material for the cutting process.

The efficiency of a boring machine is determined by the speed at which it can cut into the material. This is determined by the power of the motor and the speed of the spindle. The cutting tool must also be sharp and properly aligned to ensure that it can cut quickly and accurately.

Boring machines are also designed to be easy to use and maintain. The spindle and cutting tool can be easily adjusted to ensure that they are properly aligned and that the cutting process is as efficient as possible. The table can also be adjusted to ensure that the material is properly positioned for the cutting process.

Boring machines are essential tools for ensuring accuracy and efficiency in a variety of industrial and manufacturing processes. They are designed to create precise, uniform holes with a high degree of accuracy and repeatability. They are also designed to be easy to use and maintain, ensuring that they can be used to create accurate and efficient holes quickly and easily.