WEISH CNC MASTER is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

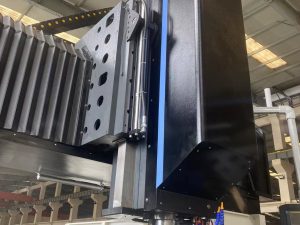

Weish 3 axis milling machine is a tool designed for automated, efficient and accurate production of components. It is computer-controlled and can carry out complex tasks with precision and accuracy. This technology has been adopted by various industries including aerospace, defense, automotive, and medical, to reduce cost and increase production efficiency. It is capable of cutting intricate patterns and shapes with great accuracy while reducing material waste, making it an ideal choice for mass production.

Weish 3 axis milling machine is a computer-controlled machine tool used for manufacturing components in a wide range of industries. It is designed for quick and accurate creation of complex parts with the help of sensors and feedback systems. Its ability to fabricate intricate components with minor adjustments and a high degree of accuracy makes it a popular choice for automating processes and increasing industrial production.

Why choose us?

- 1Weish CNC commitment is to support our customers who purchase any of our machine and gives very quick reaction of any problems happened to the machineWeish Machines has a after sales service of conventional machinery with a national and international quality service that has the seal of the prestigious company TÜV Rheinland. Our commitment is to offer the best customer service from day one.

3 axis milling machine–A Guide to Frequently Asked Questions

2.Does the 3 axis milling machine have an automatic measurement and calibration system?

3.What are the sustainability and environmental characteristics of the 3 axis milling machine?

4.What are the after-sales services available for gantry milling machine?

5.Can the processing capacity of the gantry milling machine be expanded or customized?

6.What is the production capacity of the factory for cnc gantry milling machine?

7.How automated and intelligent is the 3 axis milling machine?

8.What is the research and development capability of the factory?

9.What are the dimensions and load-bearing capacity of the workbench of the gantry milling machine?

10.Does the gantry milling machine have a cooling system to control temperature?

11.What is CNC Portal milling machine and how does it work?

1.Does the portal milling machine center have a programmable control system and how to program it?

Yes. SIEMENS 828D.840D./ FANUC / GSK. 1:Tool radius compensation function (G40, G41, G42) 2:Programming incrementally. 3:Programming in absolute terms.

2.Does the 3 axis milling machine have an automatic measurement and calibration system?

3 axis milling machine adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

3.What are the sustainability and environmental characteristics of the 3 axis milling machine?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good

4.What are the after-sales services available for gantry milling machine?

Two-year warranty, Seller should assign 2 or 3 engineers come to clinet’s site for installation.

5.Can the processing capacity of the gantry milling machine be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

6.What is the production capacity of the factory for cnc gantry milling machine?

30 sets per year

7.How automated and intelligent is the 3 axis milling machine?

As the development of high technology becomes more intense, high-tech elements will also be used in the processing and manufacturing of various cargo facilities, which can not only give them special operational power but also improve the overall visual effect. In fact, if we observe the pentahedral machining center, we can also understand what kind of application effects it shows when high-tech elements are used on it. As a kind of processing facility that has attracted much attention from compatriots, after the pentahedral machining center appeared on the market, the changes it brought to many processing and manufacturing companies cannot be ignored. As people pay more attention to the goods of the facility, more and more people Many new manufacturing processes are also used in pentahedral machining centers.

8.What is the research and development capability of the factory?

Independently researched and developed, pioneering new research and development technology, and equipped with mature production capabilities,series gantry machining centers have always prioritized efficiency, high precision, and high rigidity, providing you with extremely powerful chip cutting capabilities. With more flexible options and a more complete series of specifications, it is widely used in various fields such as the automotive industry, precision molds, aerospace industry, military shipbuilding industry, etc.

9.What are the dimensions and load-bearing capacity of the workbench of the gantry milling machine?

Table size is Up to client’s requirement. Worktable loading is from 30-150 Tons

10.Does the gantry milling machine have a cooling system to control temperature?

Yes. Lubricate system. Cutting oil temp control system

11.What is CNC Portal milling machine and how does it work?

It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the numerical control device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process the parts according to the shape and size required by drawing. Working Principle When using a CNC machine tool, the geometric information and process information of the drawings of the parts to be processed must first be written into a processing program using the prescribed code and format; then the processing program is input to the CNC device, and the CNC system information is processed according to the requirements of the program. , distribution, so that each coordinate moves a certain minimum displacement amount to realize the relative movement of the tool and the workpiece to complete the processing of the part.