WEISH CNC MASTER is a national high-tech enterprise which integrates R&D, production, sales and maintenance, and has its own import and export rights.Since the establishment of the company, strictly to science and technology as the leading, market-oriented, quality as the fundamental, as a guarantee to the concept of service, has obtained the considerable development.

Many of the products and technology of a domestic first-class, powerful and enhance the core competitiveness of enterprises. Products are exported to South America, Africa, Middle East, Southeast Asia and other countries, by the praise and trust of users.

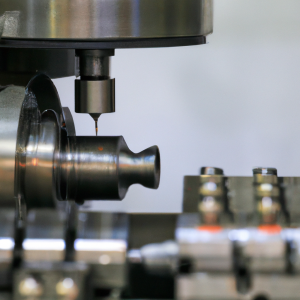

Weish automation equipment is a computer-controlled machine tool that is designed to efficiently and accurately fabricate complex components. It is used in the manufacturing of components across a wide range of industries, from aerospace and automotive to medical and telecommunications. The machine’s extremely precise cutting capabilities enable manufacturers to produce components of the highest quality, often at a fraction of the cost using traditional methods.

Weish automation equipment is a tool designed for automated, efficient and accurate production of components. It is computer-controlled and can carry out complex tasks with precision and accuracy. This technology has been adopted by various industries including aerospace, defense, automotive, and medical, to reduce cost and increase production efficiency. It is capable of cutting intricate patterns and shapes with great accuracy while reducing material waste, making it an ideal choice for mass production.

Why choose us?

- 1Weish CNC specialized technicians located at strategic points of national and international geography to carry out the installation, commissioning and maintenance of your Follow Machines.Weish CNC technicians are previously trained in the line of assembly and verification of the own brand, training that gives them a deep knowledge of the product allowing them to perform any mechanical or electronic repair of the machine in record time.

Automation equipment–A Guide to Frequently Asked Questions

2.R&D direction of CNC gantry milling machine manufacturers industry

3.Portal milling machine manufacturer service and quality system

4.What are the different sizes and models of gantry mills available?

5.What is the capacity of portal milling machine tool magazine?

6.Does the automation equipment have an automatic measurement and calibration system?

7.What are the sustainability and environmental characteristics of the automation equipment?

8.What are the advantages of automation equipment technology?

1.What industrial areas is the automation equipment suitable for?

Mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes.

2.R&D direction of CNC gantry milling machine manufacturers industry

Modularization, specialization and personalization of CNC gantry milling machine, Networking and integration of CNC gantry milling machines, Opening up of CNC gantry milling machines

3.Portal milling machine manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

4.What are the different sizes and models of gantry mills available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

5.What is the capacity of portal milling machine tool magazine?

60 Tools

6.Does the automation equipment have an automatic measurement and calibration system?

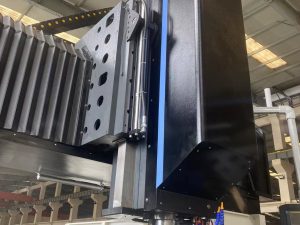

automation equipment adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

7.What are the sustainability and environmental characteristics of the automation equipment?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good

8.What are the advantages of automation equipment technology?

automation equipment can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting. , reducing the inter-process turnover time of semi-finished products and improving production efficiency.