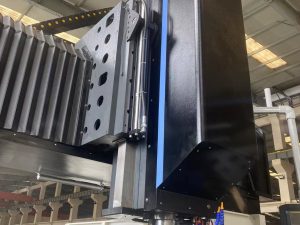

WEISH CNC MASTER has advanced production testing equipment, first-class R & D, production, sales and service teams, and behave the own production and acceptance standard higher than the national standard to ensure that each machine delivered by us can make customer satisfaction and help customer create the greatest benefits.

We focus on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.

Weish automation machines is an automated machine that works with a computer-controlled program to produce high-precision components. It is composed of motors, optical encoders, linear guides, and other components. Through the programming of these components, manufacturers can accurately and precisely process different types of materials including metals, plastics, and composites. The efficiency and accuracy of CNC machining allow efficiency production of components in various industries, such as automotive, aerospace, and medical, reducing cost and increasing quality.

Weish automation machines is a computer-controlled machine tool that is designed to efficiently and accurately fabricate complex components. It is used in the manufacturing of components across a wide range of industries, from aerospace and automotive to medical and telecommunications. The machine’s extremely precise cutting capabilities enable manufacturers to produce components of the highest quality, often at a fraction of the cost using traditional methods.

Why choose us?

- 1Weish Machines has an exhaustive quality control for each of its machines which makes us leaders in conventional machinery. Our expert mechanics take great care to verify each and every phase of the assembly of the machines in our facilities giving a three-year guarantee on parts.Our commitment is to offer our customers a long-lasting product in optimal conditions for machining once it arrives at their facilities.That is why we have ISO 9001 and TÜV Rheinland certification, which keeps us at the forefront of machine tools.

automation machines–A Guide to Frequently Asked Questions

2.Does the gantry milling machine device have an automated loading and unloading system?

3.Can the processing capacity of the gantry milling machine be expanded or customized?

4.What industrial areas is the automation machines suitable for?

5.Does the portal milling machine center support multi tasking?

6.What is the production capacity of the factory for cnc gantry milling machine?

7.What is the working noise level of the cnc gantry milling machine?

8.What is the main purpose of the automation machines?

9.What impact does the automation machines have on society?

10.Is the portal milling machine center equipped with a tool and workpiece clamping system?

11.What is CNC Portal milling machine and how does it work?

1.Does the automation machines have an automatic measurement and calibration system?

automation machines adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

2.Does the gantry milling machine device have an automated loading and unloading system?

Yes. Robot

3.Can the processing capacity of the gantry milling machine be expanded or customized?

Yes. We can make the gantry milling machine in Professional customization

4.What industrial areas is the automation machines suitable for?

Mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes.

5.Does the portal milling machine center support multi tasking?

Yes. Five facing machining, 5 axis machining. 3+2 axis machining.

6.What is the production capacity of the factory for cnc gantry milling machine?

30 sets per year

7.What is the working noise level of the cnc gantry milling machine?

<70DB

8.What is the main purpose of the automation machines?

automation machines have many uses and are mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes. Today, the technical level of CNC gantry milling machines can determine a company’s position in the industry and even become a standard for measuring the modernization of a country’s manufacturing industry.

9.What impact does the automation machines have on society?

Due to the increasingly fierce market competition, there are more and more high value-added customization needs. The industry not only needs a production system, logistics system, and after-sales service system with rapid response capabilities, but also requires automated process control and a more humane information flow system to turn customized needs into measures that can be implemented in practice.

10.Is the portal milling machine center equipped with a tool and workpiece clamping system?

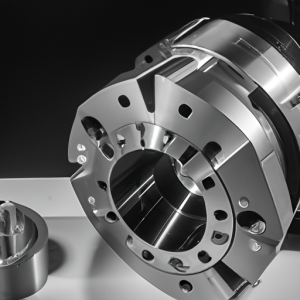

Yes. Hydraulic chuck

11.What is CNC Portal milling machine and how does it work?

It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the numerical control device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process the parts according to the shape and size required by drawing. Working Principle When using a CNC machine tool, the geometric information and process information of the drawings of the parts to be processed must first be written into a processing program using the prescribed code and format; then the processing program is input to the CNC device, and the CNC system information is processed according to the requirements of the program. , distribution, so that each coordinate moves a certain minimum displacement amount to realize the relative movement of the tool and the workpiece to complete the processing of the part.