The big promotion has raised implicit anxiety in the CNC machine center industry.

Many manufacturers specialize in CNC turning machine, which are improved on the basis of ordinary lathes. I bought it from a regular lathe manufacturer.

Many manufacturers choose four or six original parking machine tools, and the spindle speed is composed of a frequency converter, variable frequency AC transmission, and multiple sets of CNC systems.

The original lathes are all dual spindle, but the CNC transformation of dual spindle CNC turning machine must be completed by replacing the two spindles with each other.

The dual spindle CNC turning machine system is designed to solve the problem of variable component products, easy whirlwind in single spindle CNC turning machine processing, and single spindle dual feed CNC turning machine.

The dual spindle CNC turning machine uses the dual spindle CNC turning machine, also known as the machine tool. The dual spindle CNC turning machine is a high-precision and high-performance small CNC turning machine. It is an advanced, economical, and practical metal processing equipment.

A dual spindle CNC turning machine refers to a device that carries and cuts various parts of the workpiece. It is a composite CNC turning machine with feed motion and spindle motion. Can process various complex parts.

A dual spindle CNC turning machine belongs to the metal cutting type of lathe, which can simultaneously complete complex machining processes such as turning, drilling, and milling on the lathe. There are two types of structures for dual spindle CNC turning machine, one is a dual spindle CNC turning machine (i.e. a dual spindle CNC turning machine); Another type is a dual spindle CNC turning machine (i.e. dual spindle CNC turning machine). The following introduces the structural characteristics of a dual spindle CNC turning machine.

Double spindle CNC turning machine: adopting a four station horizontal structure; Short break-in time, good functional rigidity, exquisite appearance, light weight, and durability.

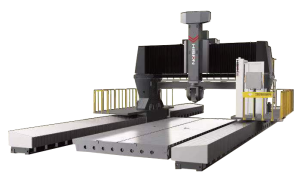

Horizontal CNC turning machine: The horizontal layout of the bed body, spindle box, feed box, etc. adopts a frame structure, as shown in Figure 12.

Single tool holder, with a feed rate of 001mm and a feed rate of 0-2mm/min, to improve machining efficiency and reduce machining costs.

Tailstock: Lathe manufacturers usually drill a 190mm hole first, followed by a 221mm hole. The tailstock is used to meet the needs of length and shape