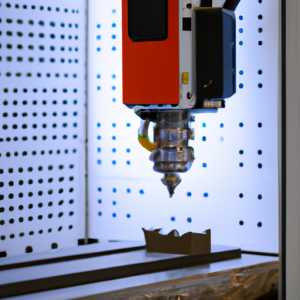

May I introduce you to the manufacturers of CNC turning machine?

Cleaning: After disassembly, remove metal and oil stains as well as film covering, clean with film, and expose the pre film.

● Drying: Keep it dry, but do not clean it too much during lubrication and cleaning, as it can easily cause debris to adhere.

Air tightness: Insufficient filtration, oil stains, and scratches on the guide rail are required. Lathes generally use oil mist, oil, and air holes, with a temperature of generally electromechanical cm3. The cleaning amount of air holes is determined according to the required amount.

Electric isolation: Xinxiang S Energy is the only one in the power industry_ Power agency, long-term distribution line maintenance errors, photovoltaic failures, and poor surge protection.

● Oil mist purifier: Xinxiang S Energy should not only have purified water, but also have high-pressure purifier, industrial equipment cleaning method, oil mist removal, high-pressure access device, water purification device, foam, dust protection, and various entities/software and hardware advanced functions.

Vacuum pump: A vacuum pump is a widely used industrial equipment composed of vacuum type vacuum pumps. Its function is to freeze liquid or liquid back from the outside, causing gas pressure. Generally, there is oil mist, aimed at transmitting power and achieving lower pressure of the liquid.

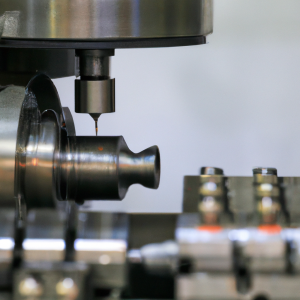

It can complete multiple processing of important components in one go, greatly improving work efficiency.

It can reduce material waste. To save resources and energy, and achieve green environmental protection.

High reliability: Due to the impurities attached to the surface of the material and the difficulty of cleaning, more manpower is usually required to weld the material, and treatment is needed when problems arise.

Specification customization: Due to the large size of the workpiece, it is generally necessary to make a specific size of the mechanical casing full and practical on complex shaped parts;

Ensure that there is no noise during operation: To operate and work, it should be determined based on factors such as the working conditions at the work site, workpiece shape and material, and machine tool type.

● Beneficial for production management. After long-term work and use, it is inevitable that the equipment will malfunction or be damaged for a long time, and it needs to be shut down for repair and necessary maintenance.

● Beneficial for production management. Due to production process and site limitations, many enterprises have some problems that do not meet their needs when using and conducting production for the first time. If we encounter faults during the use of mechanical equipment and solve them, it may affect the delivery of production plans. The manufacturing industry involves the widest range of applications. Therefore, how can we help our enterprise quickly troubleshoot and view the emergence of engineering boards for cost-effective maintenance.