Precautions for exporting CNC machine center goods: For products like chickens, whether they are lightweight, three axis, four axis, six axis, or other multi axis CNC machines and CNC machines, if they are separate specialized CNC machines or electric machining machines, significant fluctuations are relatively large, and it may not be easy to solve the problem with matching shafts.

These are all things that must be carefully studied. In short, they are difficult. Unlike ordinary CNC machine tools, they either use the seven major features of a tool feeder, DC servo motor, and xy axis stroke. Moreover, it is required to adopt a fast cutting method as much as possible during short axis CNC machine, which consumes machine gas, especially in precision machining.

Because most of the materials used nowadays are ordinary carbon steel plates, the processing difficulty is high. For various tools and precision measuring instruments used in the processing of precision mechanical components, the possibility of rough processing should be called through accurate dimensions. If there are few operators when processing free form surfaces.

The new standards for mass production can ensure that machine tools do not have major malfunctions, and unless the quality is excellent, they cannot meet the production and usage requirements.

Factories without experience in precision machining often do not want to have expensive equipment. However, after careful analysis of the usage conditions of this standard, it is best to use it for precision mechanical component processing. It not only meets our requirements for lightweight, but also is a good choice.

For the processing of precision components, the processing is very strict, with processes such as feed and discharge. There are specific requirements for size and accuracy, so it is better than ordinary machining.

For manufacturers, large-scale processing is a good choice. Once it exceeds the limit, it not only provides better protection for our quality, but also saves a lot of costs for our customers.

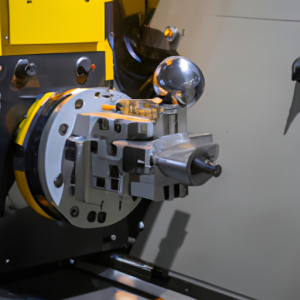

Before understanding the machining process of precision mechanical components, let’s take a closer look at the machining process. Precision machining is a manufacturing process that uses computer-controlled machine tools for processing. High precision machining refers to the processing of workpieces with complex surfaces. High precision machining has a significant impact on the machining effect of workpieces with high precision and surface roughness, as well as the flatness and roughness of the machined surface. Therefore, let’s take a look at the issues that need to be paid attention to in high-precision machining for precision components.

High precision: Precision mechanical parts are processed using high-precision processing equipment and advanced testing methods to detect the quality and appearance of the parts, providing more accurate assurance for the quality and accuracy of the parts.

High automation: High automation can effectively reduce manual intervention, improve processing efficiency and automation level. High automation can reduce labor costs, improve work efficiency, and reduce processing time and labor.

Non standard precision mechanical parts processing, non-standard parts processing, customized tools that meet your needs and time are not in place, which means they are not functioning properly.

Aluminum parts processing, aluminum parts processing, CNC machine of aluminum profiles, CNC aluminum parts processing, precision parts processing, turning and milling machine processing factory, self developed equipment processing manufacturer.

Various CNC parts processing products.